Twist drill bit HSCo8 WN MAGMA

Twist drill, HSCo8, WN type, RH MAGMA

DRL-TWST-MET-WN-HSCO8-MAGMA-D10,2

Art.-no. 0618941020

EAN 4061975572875

price per selected packing unit | Individual prices for customers after login

Register now and access more than 125,000 products

Exceptionally high drilling stability and cutting force

Reinforced core and shortened spiral length according to DIN 1897 with a total length according to DIN 338

Extra-high level of resistance to breakage

Optimised cutting edge and special, flat helix angle

Special magma multi-layer coating and 8 % cobalt alloy

- Up to 9x longer service life and up to 50 % faster cutting speed compared to uncoated drill bits

- Up to 2x longer service life compared to conventional coatings

- Heat-resistant up to 800 °C

Optimal centring during work and less effort required

135° tip angle and optimised cross web thinning

3-flat shank (from dia. 4 mm)

- No spinning in the drill chuck: faster, more comfortable working

- Optimal power transmission

- Protects the drill chuck from damage

- Minimal effort required to loosen and tighten the drill chuck

Product packaging made from 100 % PCR (recycled plastic from household waste) and 100 % recyclable

Datasheets(X)

- Materials that are difficult to machine (e.g. Hardox 400–500), such as excavator shovels, lorry attachments, armour plating, snow ploughs, agricultural machinery etc.

- Holes in conventional steels where a long service life is required

Where possible, use sufficient coolant and lubricant.

| |

Suitable for machine type | Drill, Cordless screwdrivers, Pedestal drilling machine, Milling/drill center |

Material to be processed | Hard and tough material |

Quality | ZEBRA-Premium |

Standard / drilling depth | CS / 3xD |

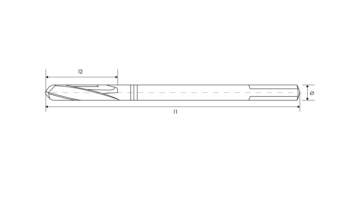

Diameter (Ø) | 10.2 mm |

Length (l1) | 133 mm |

Chip flute length (l2) | 43 mm |

Shank diameter | 10.2 mm |

Shank style | 3-face shank |

Surface | Magma multilayer coating |

Cutting material | HSCo8 |

Type | RH |

Angle of the tip | 135 Degree |

Service life (points system) | 4 of 4 points |

Drilling speed (point system) | 3 of 4 points |

Bore hole quality (point system) ( ) | 4 of 4 points |

Versatility (points system) | 2 of 4 points |

Drilling behaviour (point system) | 4 of 4 points |

Suitable for drill (points system) | 4 of 4 points |

Suitable for cordless drills (points system) | 4 of 4 points |

Suitable for upright drilling machine (points system) | 4 of 4 points |

Suitable for milling-drilling centre (points system) | 3 of 4 points |

Self-centring | Yes |

Suitable for tensile strength up to | 1550 N/mm² |

Material of sub-group | Alloyed tempering steels, Nitriding steels, Tool steels, High-speed steels, Cast iron, Ductile iron, Malleable cast iron, Titanium, Titanium alloys, Hardox, Spring steels, Bronze, short-chipping, Bronze, long-chipping, Brass, short-chipping |

| Cutting values | ||||||||||||

| For dia. 1.0-3.0 | ||||||||||||

| Material designation | Tensile strength | from dia. 1.0 | from dia. 2.0 | from dia. 3.0 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| Unalloyed quenched and tempered steels | ≤ 1,000 N/mm² | 20 | 25 | 6360 | 7960 | 0,020 | 3183 | 3979 | 0,030 | 2122 | 2653 | 0,040 |

| Low-alloy quenched and tempered steels | ≤ 1,000 N/mm² | 20 | 25 | 6360 | 7960 | 0,020 | 3183 | 3979 | 0,030 | 2122 | 2653 | 0,040 |

| Alloyed quenched and tempered steels | ≤ 1,200 N/mm² | 8 | 12 | 2546 | 3820 | 0,020 | 1273 | 1910 | 0,030 | 849 | 1273 | 0,040 |

| Nitriding steels | ≤ 1,200 N/mm² | 8 | 12 | 2546 | 3820 | 0,020 | 1273 | 1910 | 0,030 | 849 | 1273 | 0,040 |

| Tool steels | ≤ 1,200 N/mm² | 8 | 12 | 2546 | 3820 | 0,020 | 1273 | 1910 | 0,030 | 849 | 1273 | 0,040 |

| High-speed steels | ≤ 1,200 N/mm² | 8 | 12 | 2546 | 3820 | 0,020 | 1273 | 1910 | 0,030 | 849 | 1273 | 0,040 |

| Stainless steels | ||||||||||||

| Titanium and titanium alloys | ≤ 850 N/mm² | 7 | 10 | 2228 | 3183 | 0,020 | 1114 | 1592 | 0,030 | 743 | 1061 | 0,040 |

| Special alloys | ≤ 1,200 N/mm² | 7 | 9 | 2228 | 2865 | 0,020 | 1114 | 1432 | 0,030 | 743 | 955 | 0,040 |

| Cast metals | ||||||||||||

| Cast iron | ≤ 350 HB | 20 | 30 | 6366 | 9550 | 0,030 | 3183 | 4775 | 0,040 | 2122 | 3183 | 0,050 |

| Spheroidal graphite and malleable iron | ≤ 350 HB | 18 | 22 | 5730 | 7000 | 0,030 | 2865 | 3500 | 0,040 | 1910 | 2334 | 0,050 |

| Hard materials | ||||||||||||

| Hardox | ≤ 1,250 N/mm² | 7 | 9 | 2228 | 2865 | 0,025 | 1114 | 1432 | 0,035 | 743 | 955 | 0,045 |

| Hardox | ≤ 1,550 N/mm² | 4 | 6 | 1273 | 1910 | 0,015 | 637 | 955 | 0,020 | 424 | 637 | 0,030 |

| Spring steels | ≤ 1,100 N/mm² | 8 | 10 | 2538 | 3183 | 0,025 | 1273 | 1592 | 0,035 | 849 | 1061 | 0,040 |

| Key |

| vc = cutting speed [m/min] |

| f = feed [mm/r] |

| n = rotation speed [rpm] |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| For dia. 8.0-12.0 | ||||||||||||

| Material designation | Tensile strength | from dia. 8.0 | from dia. 10.0 | from dia. 12.0 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| Unalloyed quenched and tempered steels | ≤ 1,000 N/mm² | 20 | 25 | 796 | 995 | 0,100 | 637 | 796 | 0,120 | 531 | 663 | 0,140 |

| Low-alloy quenched and tempered steels | ≤ 1,000 N/mm² | 20 | 25 | 796 | 995 | 0,100 | 637 | 796 | 0,120 | 531 | 663 | 0,140 |

| Alloyed quenched and tempered steels | ≤ 1,200 N/mm² | 8 | 12 | 318 | 477 | 0,100 | 255 | 382 | 0,120 | 212 | 318 | 0,140 |

| Nitriding steels | ≤ 1,200 N/mm² | 8 | 12 | 318 | 477 | 0,100 | 255 | 382 | 0,120 | 212 | 318 | 0,140 |

| Tool steels | ≤ 1,200 N/mm² | 8 | 12 | 318 | 477 | 0,100 | 255 | 382 | 0,120 | 212 | 318 | 0,140 |

| High-speed steels | ≤ 1,200 N/mm² | 8 | 12 | 318 | 477 | 0,100 | 255 | 382 | 0,120 | 212 | 318 | 0,140 |

| Stainless steels | ||||||||||||

| Titanium and titanium alloys | ≤ 850 N/mm² | 7 | 10 | 279 | 398 | 0,100 | 223 | 318 | 0,120 | 186 | 265 | 0,140 |

| Special alloys | ≤ 1,200 N/mm² | 7 | 9 | 279 | 358 | 0,100 | 223 | 286 | 0,120 | 186 | 239 | 0,140 |

| Cast metals | ||||||||||||

| Cast iron | ≤ 350 HB | 20 | 30 | 796 | 1194 | 0,120 | 637 | 955 | 0,140 | 531 | 796 | 0,160 |

| Spheroidal graphite and malleable iron | ≤ 350 HB | 18 | 22 | 716 | 875 | 0,120 | 573 | 700 | 0,140 | 477 | 584 | 0,160 |

| Hard materials | ||||||||||||

| Hardox | ≤ 1,250 N/mm² | 7 | 9 | 279 | 358 | 0,100 | 223 | 286 | 0,125 | 186 | 239 | 0,140 |

| Hardox | ≤ 1,550 N/mm² | 4 | 6 | 159 | 239 | 0,080 | 127 | 191 | 0,100 | 106 | 159 | 0,110 |

| Spring steels | ≤ 1,100 N/mm² | 8 | 10 | 318 | 398 | 0,100 | 255 | 318 | 0,125 | 212 | 265 | 0,140 |

| For dia. 4.0-6.0 | ||||||||||||

| Material designation | Tensile strength | from dia. 4.0 | from dia. 5.0 | from dia. 6.0 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| Unalloyed quenched and tempered steels | ≤ 1,000 N/mm² | 20 | 25 | 1592 | 1989 | 0,050 | 1273 | 1592 | 0,060 | 1061 | 1326 | 0,080 |

| Low-alloy quenched and tempered steels | ≤ 1,000 N/mm² | 20 | 25 | 1592 | 1989 | 0,050 | 1273 | 1592 | 0,060 | 1061 | 1326 | 0,080 |

| Alloyed quenched and tempered steels | ≤ 1,200 N/mm² | 8 | 12 | 637 | 955 | 0,050 | 509 | 764 | 0,060 | 424 | 637 | 0,080 |

| Nitriding steels | ≤ 1,200 N/mm² | 8 | 12 | 637 | 955 | 0,050 | 509 | 764 | 0,060 | 424 | 637 | 0,080 |

| Tool steels | ≤ 1,200 N/mm² | 8 | 12 | 637 | 955 | 0,050 | 509 | 764 | 0,060 | 424 | 637 | 0,080 |

| High-speed steels | ≤ 1,200 N/mm² | 8 | 12 | 637 | 955 | 0,050 | 509 | 764 | 0,060 | 424 | 637 | 0,080 |

| Stainless steels | ||||||||||||

| Titanium and titanium alloys | ≤ 850 N/mm² | 7 | 10 | 557 | 796 | 0,050 | 446 | 637 | 0,060 | 371 | 531 | 0,080 |

| Special alloys | ≤ 1,200 N/mm² | 7 | 9 | 557 | 716 | 0,050 | 446 | 573 | 0,060 | 371 | 477 | 0,080 |

| Cast metals | ||||||||||||

| Cast iron | ≤ 350 HB | 20 | 30 | 1592 | 2387 | 0,060 | 1273 | 1910 | 0,080 | 1061 | 1592 | 0,100 |

| Spheroidal graphite and malleable iron | ≤ 350 HB | 18 | 22 | 1432 | 1751 | 0,060 | 1146 | 1401 | 0,080 | 955 | 1167 | 0,100 |

| Hard materials | ||||||||||||

| Hardox | ≤ 1,250 N/mm² | 7 | 9 | 557 | 716 | 0,063 | 446 | 573 | 0,070 | 371 | 477 | 0,080 |

| Hardox | ≤ 1,550 N/mm² | 4 | 6 | 318 | 477 | 0,040 | 255 | 382 | 0,050 | 212 | 318 | 0,060 |

| Spring steels | ≤ 1,100 N/mm² | 8 | 10 | 637 | 796 | 0,060 | 509 | 637 | 0,070 | 424 | 531 | 0,080 |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!