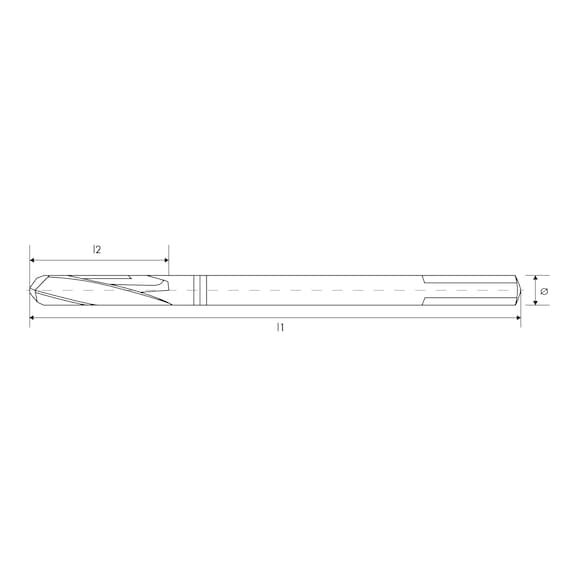

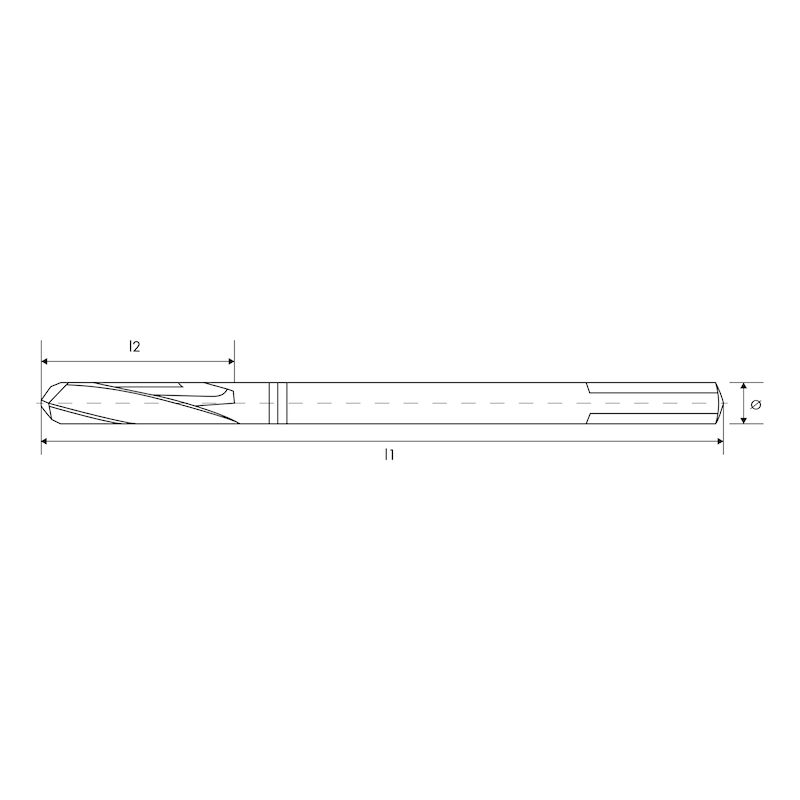

The images are examples. For detailed information, other images and documents, please select individual articles from the following table.

Twist drill bit HSCo8 WN MAGMA

The extremely long-lasting drill bit with Magma multi-layer coating and 8 % cobalt alloy for universal processing of conventional steels, titanium and hard-to-machine materials (e.g. Hardox) with high strengths up to 1550 N/mm².

Register now and access more than 125,000 products

Variants

Exceptionally high drilling stability and cutting force

Reinforced core and shortened spiral length according to DIN 1897 with a total length according to DIN 338

Extra-high breakage resistance

Optimised cutting edge and special, flat spiral angle

Special Magma multilayer coating and 8% cobalt alloy

- Up to 9 times longer service life and up to 50% higher cutting speed compared to uncoated drills

- Up to 2 times longer service life compared to conventional coatings

- Heat resistant up to 800°C

Outstanding centring during work and reduction in force required

135° tip angle and optimised cross thinning

3-face shank (from Ø 4 mm)

- No twisting in the drill chuck: faster, more comfortable working

- Optimum transmission of forces

- Protection of the drill chuck from damage

- Little effort required to open and close the drill chuck

- Materials that are difficult to machine (e.g. Hardox 400–500), such as excavator shovels, lorry attachments, armour plating, snow ploughs, agricultural machinery etc.

- Holes in conventional steels where a long service life is required

Where possible, use sufficient coolant and lubricant.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!