The images are examples. For detailed information, other images and documents, please select individual articles from the following table.

Register now and access more than 125,000 products

Variants

Bi-metal (carrier made of spring steel, teeth made of cobalt steel M42)

New unique, patented tooth shape made from M42 bi-metal (WO 02/42029 A1)

- Easy band selection, as just three tooth types cover a wide variety of applications and material thicknesses.

- Cost saving thanks to minimal setup and auxiliary process times

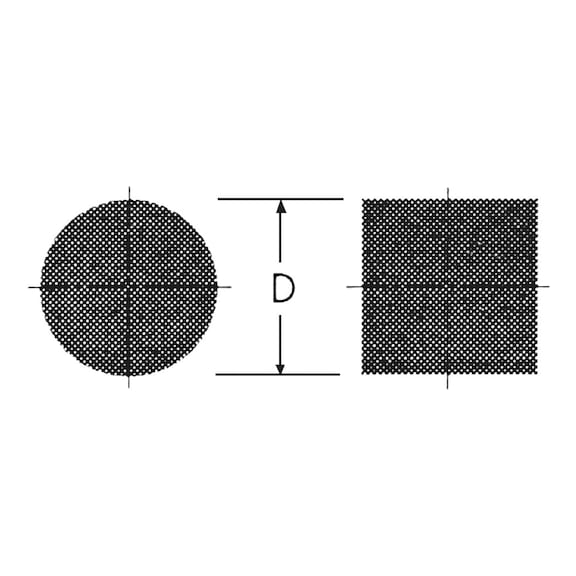

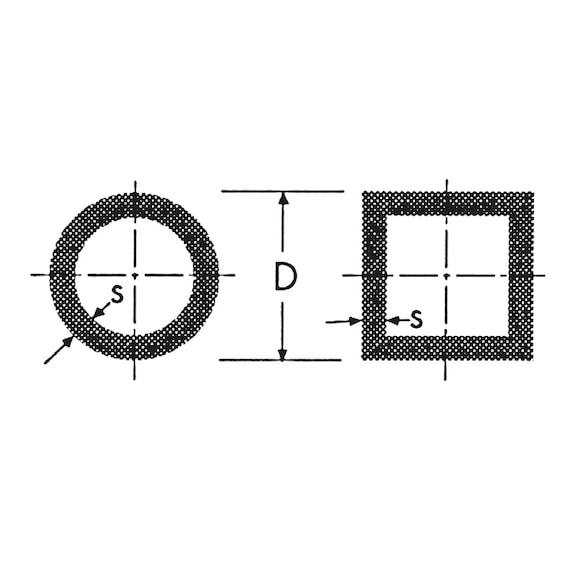

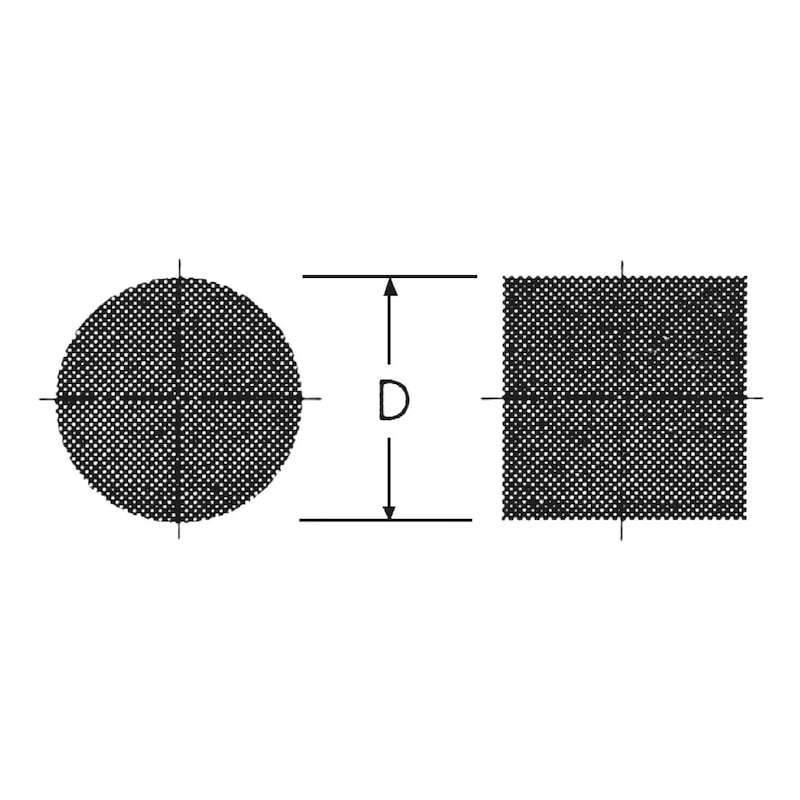

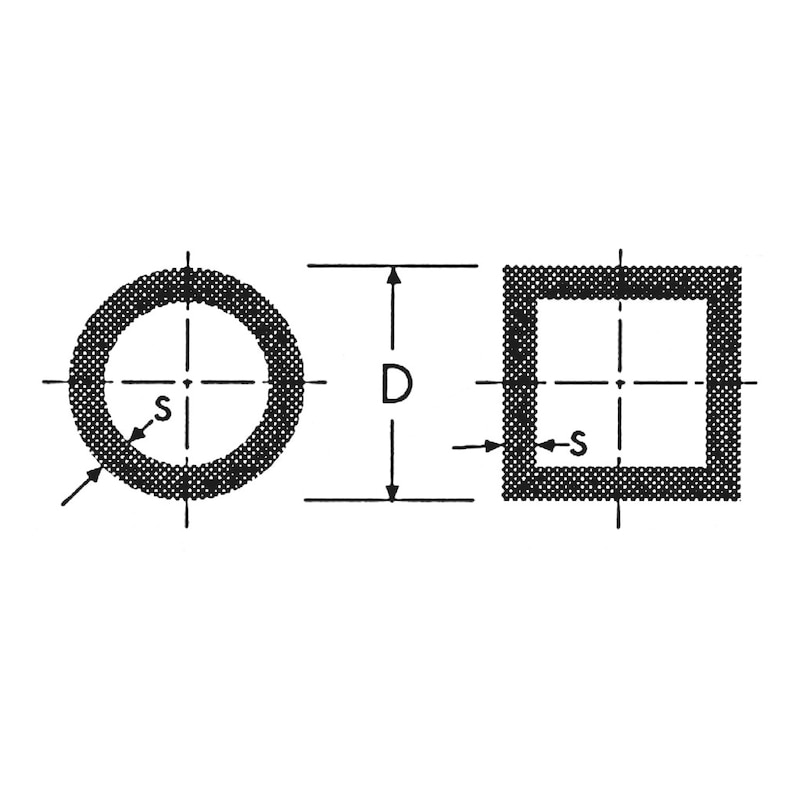

- Very versatile, can be used for applications such as solid materials, pipes, profiles, bundles and contours

- Trouble-free sawing of a wide range of materials, including construction steels, stainless steels, tool steels, cast metals, non-ferrous metals (aluminium, copper and brass) and even plastic.

Strengthened tooth backs

- 2–3 x longer service life than conventional band saw blades

- Cost saving thanks to minimal setup and auxiliary process times

The M42 tooth tips are highly heat resistant and very powerful, regardless of the coolant used.

The ZEBRA multi-use bandsaw blade is an aggressive tool and has a high penetration capacity; for this reason, the user must observe the following points:

- Tension the saw blade well to prevent oscillation at the teeth.

- Carefully guide the saw blade to the material to be cut.

- Apply moderate pressure (approx. 30–40% less than conventional saw blades), especially when cutting profiles.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!