For detailed information, other images and documents, please select individual articles from the following table.

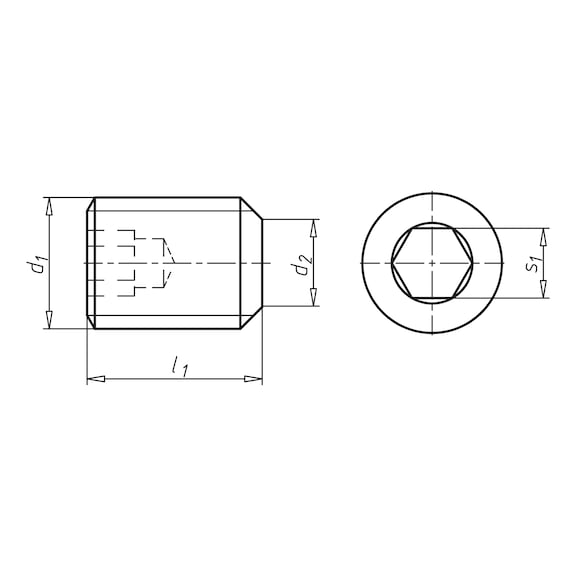

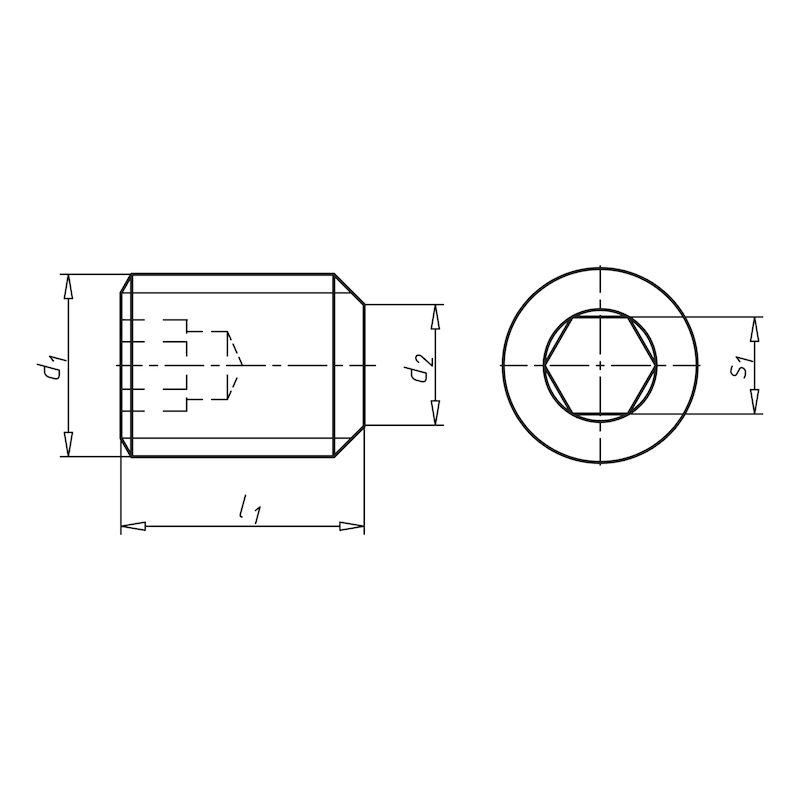

Hexagon socket set screw with ring cutter ISO 4029, steel 45H, zinc-nickel, black (ZNBHL)

Register now and access more than 125,000 products

Variants

Connection elements with a galvanised chrome (VI)-free zinc-nickel coating (ZNBHL black or ZNSHL silver) are suitable for applications with a high risk of corrosion. The coating comprises a zinc-nickel alloy layer and a seal (top coat with integrated lubricating particles).

Overview of advantages:

- Corrosion resistance of up to 720 hrs to base metal corrosion in accordance with DIN EN ISO 9227 NSS

- Adjusted friction coefficient range from 0.09μ - 0.14μ due to top coat with integrated lubricating particles

- thermal capacity up to up to 120°C

- Even coat distribution

- Functional and decorative

Hardness class 45H corresponds to a hardness of 450 HV

Steel set screws are intended for use under compressive stress only (see also DIN EN ISO 898-5). Typical uses include clamping in an adjusting ring or applying pressure to a counterpart. Steel set screws are therefore extremely hard in order to ensure torsional strength in the hexagon socket during tightening/loosening.

Tip:

A2/A4 stainless steel set screws are not specially hardened and may be used for tensile loads.

ISO 4029 replaces DIN 916 | There is some similarity | Nominal diameters for M1.4, M1.8, M14, M18, M22 are removed | Hardness classes for stainless steels introduced.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!