For detailed information, other images and documents, please select individual articles from the following table.

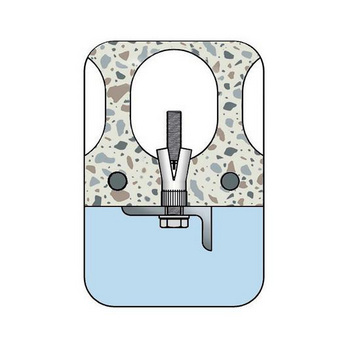

Hollow-ceiling anchor W-HD

Female thread anchor with metric thread for secure anchoring in hollow-core prestressed concrete ceilings. With technical approval. Steel, zinc-plated

Register now and access more than 125,000 products

Variants

- Screws or threaded rods can be used

- The anchor can also be mounted outside the cavity axis, up to 50 mm from the prestressed strand – maximum flexibility

- Quick, easy installation – no special tool required

- Immediate load-bearing capacity – no waiting

- DIBt National technical approval Z-21.1-1832

- Fire resistance (base material: concrete C45/55 or C50/60): R30, R60, R90, R120: DIBt National technical approval Z-21.1-1832, fire protection test report no. (3526/3426)

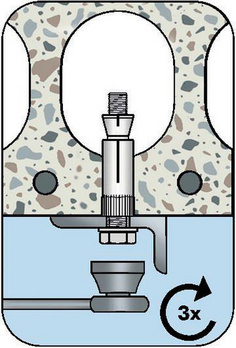

- The cone is separated from the expansion sleeve when the screw or hexagon nut is tightened. - Important: At least three screw/nut rotations are required. Applying the installation torque pulls the cone into the expansion sleeve and expands it

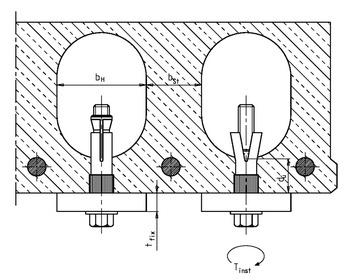

- Anchoring is only permissible in hollow-core prestressed concrete ceilings with a hollow space width that does not exceed 4.2 times the web width (bH <= 4.2 x bSt)

Key:

tfi x = thickness of the attachment

du = mirror thickness

bH = cavity width

bSt = web width

sSp = axis distance to pre-stressed strand

c = edge distance

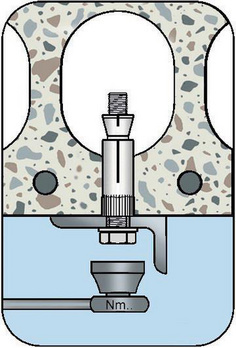

Tinst = installation torque

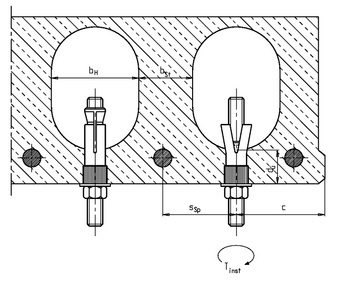

Key:

tfi x = thickness of the attachment

du = mirror thickness

bH = cavity width

bSt = web width

sSp = axis distance to pre-stressed strand

c = edge distance

Tinst = installation torque

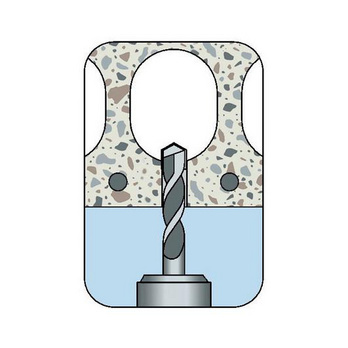

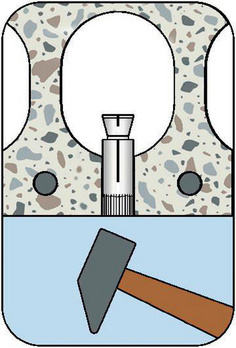

Create the drill hole

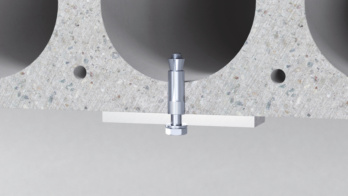

Set anchor in place

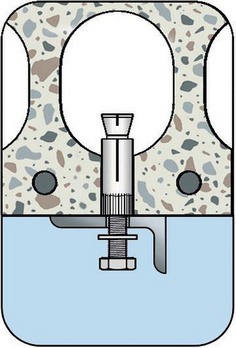

Mount component

At least three rotations of the screw - Cone separates from sleeve

Apply installation torque

Installation status

- DIBt National technical approval Z-21.1-1832

- Fire resistance (base material: concrete C45/55 or C50/60): R30, R60, R90, R120: DIBt National technical approval Z-21.1-1832, fire protection test report no. (3526/3426)

Special fastener for anchoring in hollow-core prestressed concrete ceilings

Suitable for cavities and solid zones of hollow-core prestressed concrete ceilings

Fixing points and anchors in a redundant non-structural system with approval

- Hollow-core prestressed concrete ceilings with concrete compressive strength class of C45/55 or B55

- E.g. anchoring of lightweight ceiling coverings and suspended ceilings as well as for statically comparable anchoring up to 1.0 kN/sqm and the mounting of metal structures, brackets, cable conduits, pipes, ventilation lines, suspended ceilings etc.

W-HD can be used in dry indoor areas, e.g. homes, offices, schools, hospitals, retail outlets

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!