For detailed information, other images and documents, please select individual articles from the following table.

FP connector

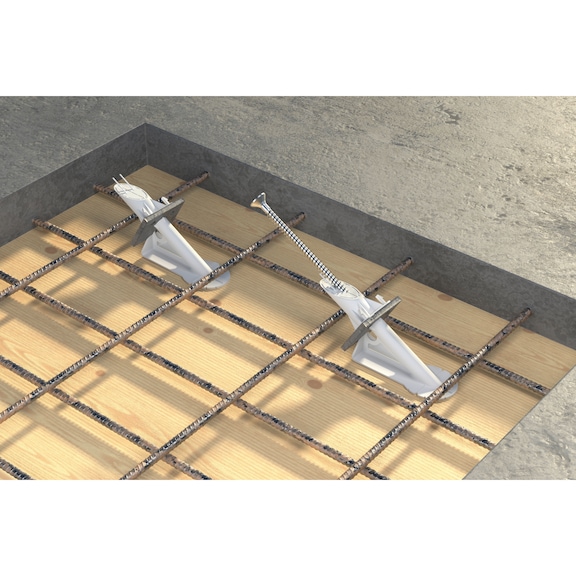

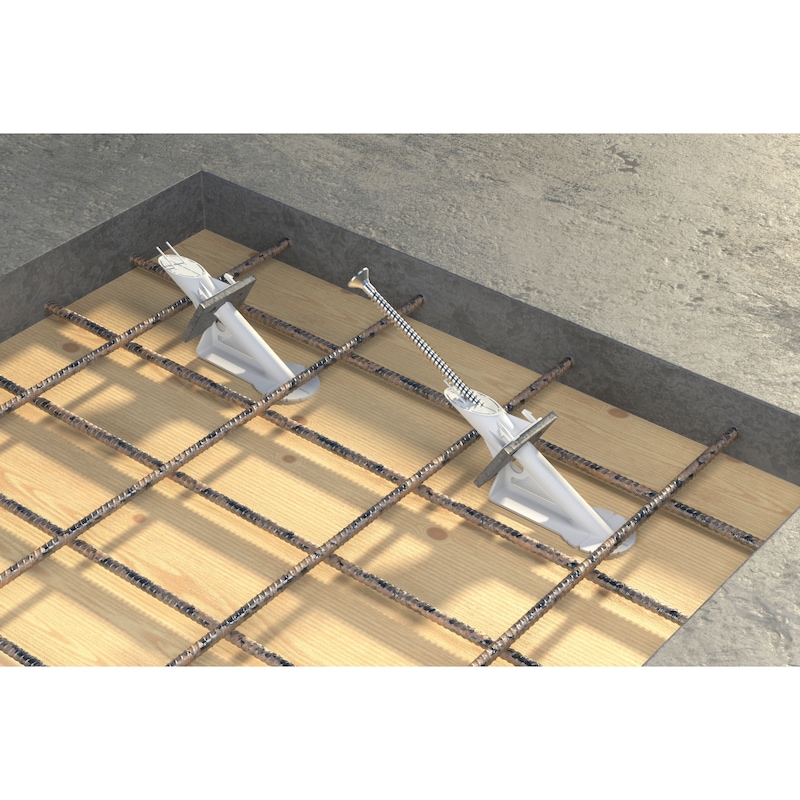

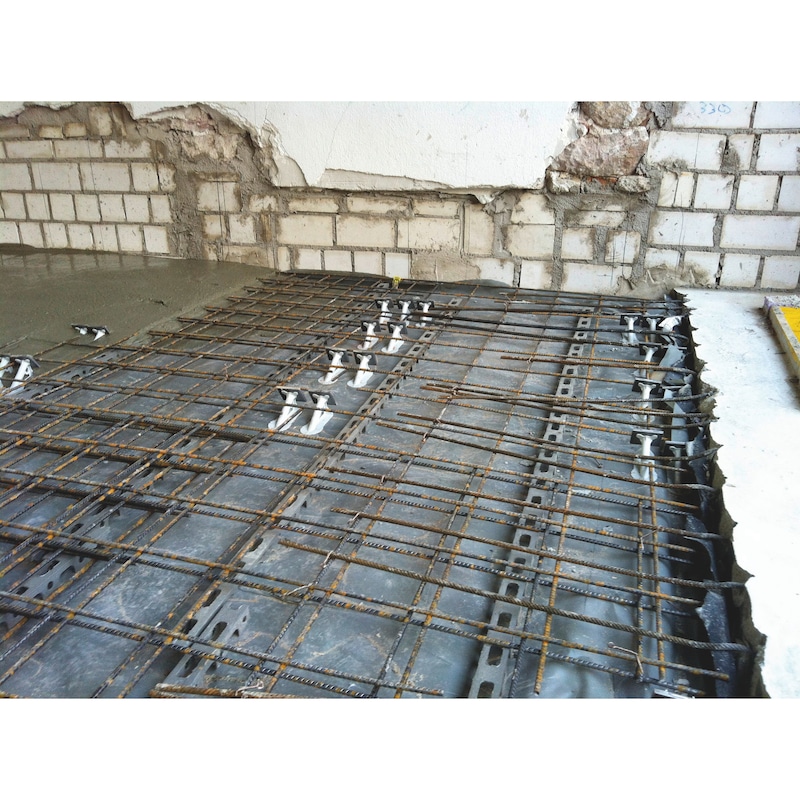

For manufacturing timber-concrete composite ceilings using wet and dry methods

Register now and access more than 125,000 products

Variants

Advantages:

- Approx. four times the load-bearing capacity of conventional WCC options with screws, allowing a reduction of the installation time

- Predetermined insertion angle

- High overall rigidity of the ceiling structure

- Helps to create joist and solid timber ceilings with longer clear spans or higher load-bearing capacities

- No licensing, high value creation of in-house production

- Flexible use in several systems

Especially for the installation of dry, precast concrete elements with integrated FT connectors:

- Very quick installation

- Full load-bearing capacity of the composite structure directly after fastening (immediate composite action)

- No waiting time while concrete is curing; construction work can continue

- No separating layer that needs to be masked

- Minimises the entry of moisture into the building as well as the swelling or shrinkage of timber parts

When using prefabricated concrete part elements:

- Merging of prefabricated concrete part elements with the wooden ceiling, without gaps, using additional ASSY 4 WH washer head screws

- Torque value (20 Nm) of the ASSYplus VG 4 countersunk head screws, 10 mm diameter for the FT connector

- To prevent the wooden ceilings shrinking after assembly, the unfinished wooden ceiling must be protected against moisture penetration

- To prevent the upper cap cover from being loosened, vibration/shaking of the element in the pre-assembled state without concrete must be avoided

- Timber dimensioning software, load tables and detailed processing instructions can be found on the service page www.wuerth.de/assy.

ETA-13/0029

Expert report (from Karlsruher Institut für Technologie (KIT)) on improving concrete strength (up to 120 mm)

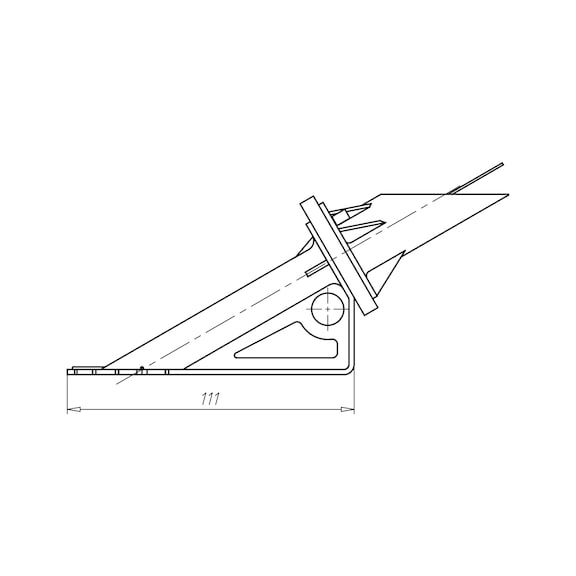

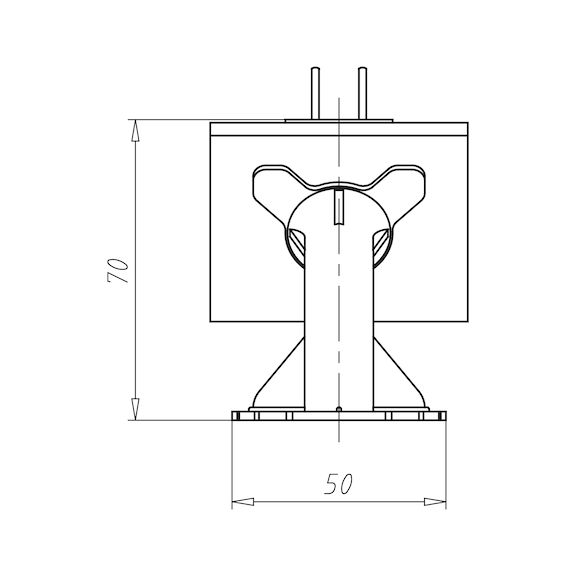

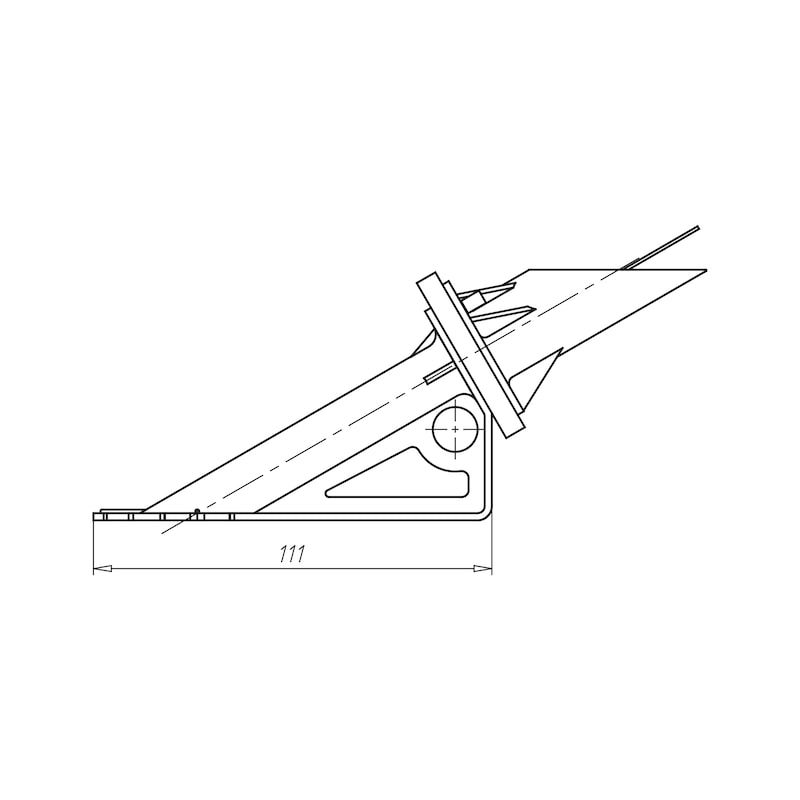

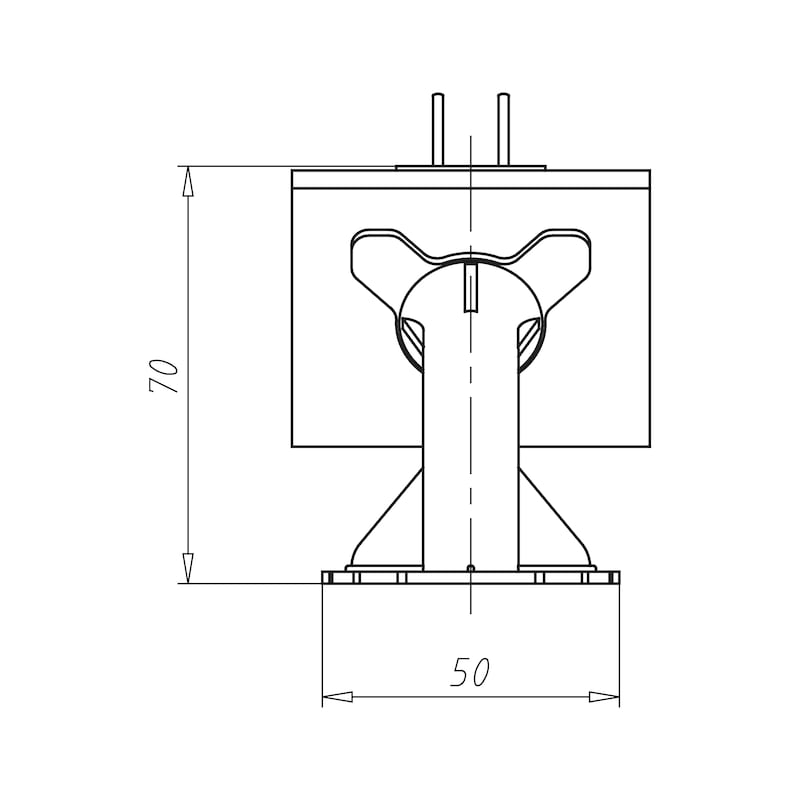

Suitable for on-the-spot installations of wood/concrete ceilings using wet concrete or for screwing pre-cast parts made by the factory (FP) with cast-in connectors to a corresponding wood ceiling system. Suitable for use in joist and solid timber ceilings. Approval for use in service class 1 and 2 (with sufficient concrete covering). Concrete strengths of 7 cm (standard) up to a maximum of 12 cm (wood lining) are possible.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!