Wheel brush Steel, knotted, with shank

Wheel brush with braided stl wire with shank

WHLBRSH-SHNK-KNOTTED-ST-D75X12X6MM

price per selected packing unit | Individual prices for customers after login

Register now and access more than 125,000 products

- Aggressive brushing effect with high wear resistance thanks to knotted wires

- Optimal access of hard-to-reach areas such as grooves and recesses

- Aggressive brushing effect due to high stiffness of the wire knots

- For use on die grinders and drills

- For optimal performance, use a tool drive with at least 500 W

- High speeds improve brush performance and service life

- Only the edge tips act on the workpiece. Excessive contact pressure does not improve the result, but it does increase the required drive power and reduces the service life of the brush.

- Always wear safety goggles and protective gloves when working with machine brushes!

Datasheets(X)

- Ideal for removing underbody seals

- Removes scale, rust, varnish, slag and rubber residues

- Deburring edges

| |

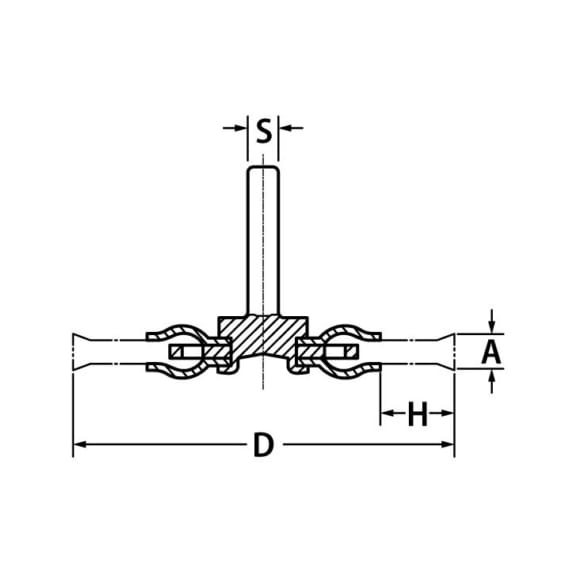

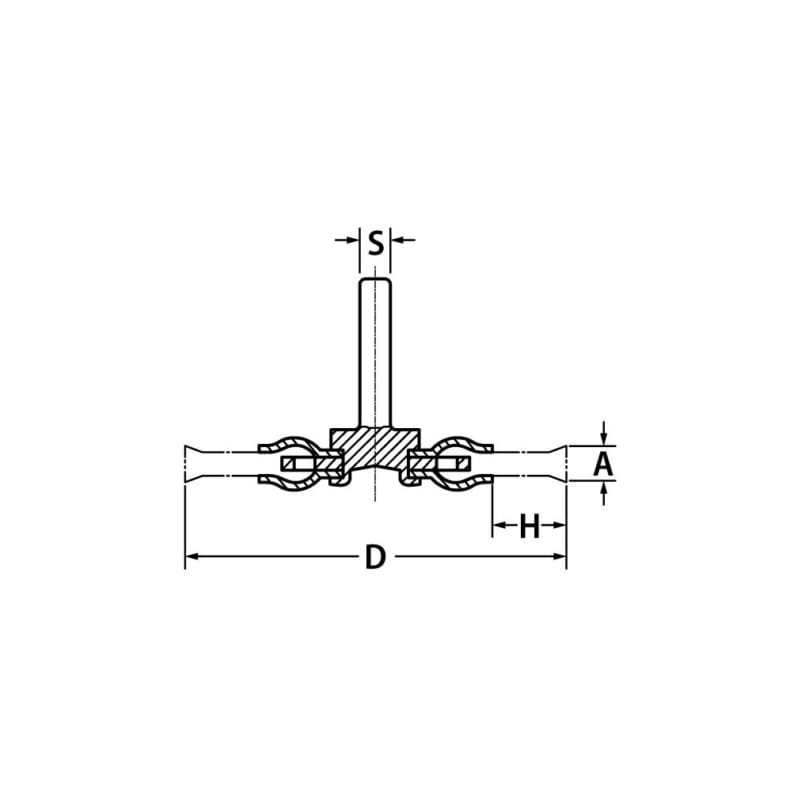

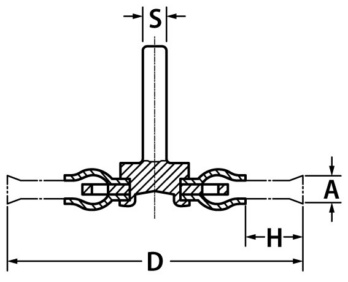

Diameter x usable width x shaft diameter (DxAxS) | 75 x 12 x 6 mm |

Usable length of wire (H) | 15 mm |

Wire diameter | 0.5 mm |

Material of wire | Steel |

Design | Braided clockwise |

Number of braids | 18 PCS |

Aggressiveness | Middle |

Suitable for cordless drills (points system) | 2 of 4 points |

Suitable for drill (points system) | 2 of 4 points |

Suitable for straight grinder (point system) | 4 of 4 points |

Max. rotation speed | 25000 1/min |

EN standard | 1083-2 |