VWM mounting bracket, complete

Mounting bracket VWM complete

MNTBRKT-COMPL-(VWM-SYS)-80X80X1200MM

Art.-no. 0479742508

EAN 4056807053158

price per selected packing unit | Individual prices for customers after login

Register now and access more than 125,000 products

VWM mounting bracket made from PUR composite with a high load-bearing capacity, together with associated insulation block

Comprehensively tested pre-wall installation system (system test by ift Rosenheim)

- Overhang of 80 mm to 200 mm can be implemented

- Simple integration into ETICS through supplied insulation block, VWM mounting bracket can be directly plastered over

- Reduction of constructive thermal bridges

- Meets the requirements of the EnEV

- Mounting bracket can be used flexibly for different window sizes

- Cutting of mounting bracket with conventional mitre saw

- Simple assembly and attachment of window element

- Secure load transfers on common application surfaces through combined bonded and mechanical attachment

- Optimum and economical sealing of window connection joint within the level of the mounting bracket

- Optimum noise protection

- Window replacement in case of renovation or repair without damaging the façade/ETICS possible

- Observe the RAL guidelines on assembly and planning of windows and house doors when planning and assembling (art. no. 5995 000 000).

- Mount according to RAL guidelines Special Case 1. If there are any special requirements, it may be necessary to consider Special Case 2.

- It is important to check that installation has been performed correctly for the specific construction conditions (e.g. weight of window casement, surface properties). When planning and selecting suitable fasteners, their properties (e.g. application surface, edge spacings, loads) need to be taken into account.

- To attach fall-proof glazing in accordance with DIN 18008-4, additional suitable and approved securing systems such as the W-ABZ window installation rail (art. no. 0479 740 XXX) must be used. Alternatively, approval is required for each individual case.

- Instructions for processing can be found in the processing guidelines/mounting instructions.

- Technical data and other product documentation can be found in the online shop.

VWM pre-wall installation system test (ift Rosenheim, test report 16-000444-PR01)

- Component testing and fitness for purpose testing for a mounting system in line with MO-02/1

- Component testing and fitness for purpose testing for a sealing system in line with MO-01/1

- Component test of mechanical security

- Load-bearing capacity of the AMO- III spacing assembly screw in the VWM mounting bracket

- Fire behaviour in accordance with EN 13501-1, class E

Component testing of the VWM pre-wall installation system (ift Rosenheim, test report 16-002416-PR01)

- Two-leaf glazed plastic door, 1960 mm x 1960 mm, casement weight: 69 kg

- Projection of 200 mm on masonry made of sand-lime brick

- Must only be secured mechanically using a W-UR 10 plastic frame anchor

- Additional vertical load: 800 N (class 4)

- Wind load: class 3

- Durability testing: 10,000 cycles (class 2)

Proof of joint sound insulation

(ift Rosenheim, test report 15-000431.PR02)

Datasheets(X)

The Würth VWM pre-wall mounting system consists of

- VWM mounting bracket

- VWM insulation block

- VWM mounting adhesive

Ideal for mounting window elements, window, balcony and terrace doors on load-bearing surfaces such as concrete and sand-lime brick, in front of the wall in the insulation layer of the ETICS, even with two-shell construction and brick facings.

The VWM mounting bracket is bonded to the supporting wall around the full circumference of the window/door opening, sealed and additionally mechanically fastened with a suitable dowel system. The mounting bracket and insulation block are precisely cut with a conventional saw (mitre saw, circular saw, jigsaw, hand saw). Offcuts can be further utilised.

- Ensure adhesion surfaces are dry, suitable, clean, dust-free and grease-free when applying.

- The mounting bracket can also be fitted to wood connector plates as an option to make it easier to align. The joints can also be bonded.

- The window elements are installed in the mounting frame, aligned and mechanically fastened.

- The window connection joint is optimally sealed on the surface of the VWM mounting bracket.

- Finally, the mounting bracket can be covered by the subsequent ETICS and directly plastered over.

Further detailed information on processing can be found in the processing guidelines/mounting instructions.

| |

Material | Functional material based on PU rigid foam |

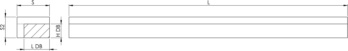

Dimension VWM (SxS2xL) | 80 x 80 x 1200 mm |

Material thickness (t) | 30 mm |

Colour | Beige |

Building material class/conditions | E - Normally inflammable / in accordance with DIN EN 13501-1 |

Heat conductance λ / conditions | 0.096 W/(m*K) / in accordance with DIN EN 12667 |

Average U-value | 0.51 W/(m²*K) |

Min./max. temperature resistance | -50 to 100 °C |

Resistance against | Humidity, Rot, Mold, Termite, Common building materials, Rotting |

Load-carrying capacity per m | 200 kg |

Shelf life from production/conditions | 24 Month / dry storage area |

Material of insulation | XPS - Extruded polystyrene |

Colour of insulation | Red |

Building material class of insulation / conditions | B1 / in accordance with DIN 4102 |

Heat conductance λ insulation / conditions | 0.034 W/(m*K) / in accordance with DIN EN 12667 |

Resistance (insulation) against | Common building materials |

Solvent resistance (insulation) | No |

Content (rm) | 12 m |

Included in delivery | 10 pcs. VWM mounting bracket 80x80x1200 mm; 10 pcs. insulation block 50x50x1200 mm; order VWM assembly adhesive separately |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!