Solvent-free assembly adhesive

Solvent-free assembly adhesive

ASMBYADH-SOLVF-CARTRIDGE-310ML

price per selected packing unit | Individual prices for customers after login

Register now and access more than 125,000 products

- Paint-compatible/can be painted over

- Resistant to ageing

- Silicone-free

- Compatible with polystyrene

- Stable

The assembly adhesive should not be used in sanitary areas, on marble/natural stone, underground, on bituminous substrates, on untreated (non-primed) metal surfaces or on joints in constant contact with moisture (e.g. concrete surfaces in contact with the ground).

The setting speed is determined by the ambient temperature and quantity of adhesive applied. This increases with high amounts of adhesive and in cold and damp conditions.

| MONTAGELIM | |||||

| Multi-klæbemasse med stor trækstyrke 0893 100 110 | Multifiberklæbemiddel 0893 100 115 | PUR Rapid 0892 100 102 | Montagelim, uden opløsningsmiddel 0893 100 100 | ||

| Kobber | ⎷5,4,1 | x | x | ⎷ | |

| Messing | ⎷5,4,1 | x | x | x | |

| Stål/jern | ⎷5,4,1 | ⎷1 | ⎷1 | ⎷1 | |

| Zink | - | x | x | ⎷ | |

| Plast | ABS | ⎷4,2 | x | x | ⎷2 |

| GRP | ⎷5 | x | x | ⎷2 | |

| Gummi/neopren | ⎷5 | x | x | - | |

| Hårdt skum | ⎷ | ⎷ | ⎷ | ⎷2 | |

| PE | - | - | - | - | |

| PMMA | - | - | - | ⎷2 | |

| Polyamid | ⎷ | - | - | - | |

| Polykarbonat | ⎷ | - | - | ⎷2 | |

| Polystyren (ikke skum!) | - | - | - | - | |

| PP | - | - | - | - | |

| PTFE | - | - | - | - | |

| PVC (ikke blød PVC!) | ⎷6 | x | - | ⎷2 | |

| Silikone | - | - | - | - | |

| Flamingo | ⎷ | ⎷ | ⎷ | ⎷ | |

| Malede overflader | Malede overflader (Malinger med to komponenter, komfuremaljer) Katodiske dypmalede paneler | ⎷5 | x | x | - |

| Træ og træmaterialer | Træ (herunder MDF, spånplade) | ⎷ | ⎷ | ⎷ | ⎷ |

| HPL-laminerede paneler (Restopal, Ultrapas) | ⎷ | ⎷ | ⎷ | ⎷ | |

| Dekorative paneler | ⎷5 | x | x | ⎷ | |

| Kork | ⎷ | ⎷ | ⎷ | ⎷ | |

| Sten- og byggematerialer | Beton | ⎷3 | ⎷3 | ⎷3 | ⎷3 |

| Bituminøse overflader | - | - | - | - | |

| Porebeton, gips, gipsplader | ⎷3 | ⎷3 | ⎷3 | ⎷3 | |

| Syntetisk sten (Korian, Varicor) | ⎷ | ⎷ | ⎷ | ⎷3 | |

| Sarte natursten (f.eks. marmor) | ⎷ | ⎷ | ⎷ | - | |

| Sten | ⎷ | ⎷ | ⎷ | ⎷ | |

| Cement-fiberplader | ⎷3 | - | - | ⎷3 | |

| Andre | Emalje | ⎷5 | - | ||

| Glas | - | - | - | - | |

| Glasfiber | ⎷ | ⎷ | ⎷ | - | |

| Spejl | - | - | - | - | |

| Porcelæn, keramik, fliser | ⎷ | ⎷ | ⎷ | - | |

| Papir | ⎷ | ⎷ | ⎷ | ⎷ | |

| Pap | ⎷ | ⎷ | ⎷ | ⎷ | |

| Væv | - | - | - | - | |

| Læder | ⎷ | ⎷ | ⎷ | - | |

| Metal | Aluminium | ⎷4,1 | ⎷4,1 | ⎷4,1 | ⎷1 |

| Ledning | - | - | - | - | |

| Rustfrit stål | ⎷5 | x | x | ⎷1 | |

| 1. Prime with Primer for Metal (art. no. 0890 100 61) 2. Prime with Primer for P/W/S (art. no. 0890 100 62) 3. Pre-treat with Penetrating Primer (art. no. 0890 545 10) 4. Pre-treat with Activating Cleaner (art. no. 0890 100 60) 5. Pre-treat with Cleaner Type 60 (art. no. 0892 130 030, 0892 130 031) 6. Pre-treat with Cleaner Type 10 (art. no. 0892 100 10) *Surface must not be wetted with lotus effect | |||||

The usage instructions are recommendations based on the tests we have conducted and on our experience; carry out your own tests before each application. Due to the large number of applications and storage and processing conditions, we do not assume any liability for a specific application result. Insofar as our free customer service provides technical information or acts as an advisory service, no responsibility is assumed by this service except where the advice or information given falls within the scope of our specified, contractually agreed service or the advisor was acting deliberately. We guarantee the consistent quality of our products. We reserve the right to make technical changes and further develop products.

Datasheets(X)

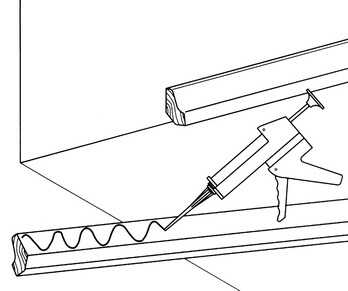

Fixing and mounting aid when installing trim and baseboards, bonding insulation, panels, sound insulation and decorative panels, wall panels, door sills, wood profiles, decorative profiles. Bonding timber constructions and repair of defects in wooden walls.

The surface must be clean, load-bearing, dry and free from dust and grease. Apply to the surface to be adhered at a spacing of 20–40 cm, with horizontal or vertical serpentine lines. Then firmly press on the joint part.

For more information, please refer to the technical data sheet.

Contents | 310 ml |

Chemical basis | Acrylate dispersion |

Colour | Light beige |

Density/conditions | 1.34 g/cm³ / in accordance with DIN 53217-2 |

Min. proportion of solids | 72 % |

Conditions for proportion of solids | in accordance with DIN 53189 |

Min./max. processing temperature | 5 to 35 °C |

Min./max. temperature resistance | -25 to +80 °C |

Stability under load | 2 mm |

Conditions for stability under load | in accordance with DIN EN 27390 |

Weight of content | 415.4 g |

Silicone-free | Yes |

Resistance against | Aging |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!