Slotted See-Through Disc

See-through flap disc

SEETHRGHFLPDISC-ZC-BR22,23-G60-D125

ZEBRA

price per selected packing unit | Individual prices for customers after login

Register now and access more than 125,000 products

Clear view of the workpiece being processed

- Prevents undesired excessive grinding.

- Reduction of processing faults.

Better surface quality as a result of more targeted work

Cool grinding due to fan effect

Reduction of temperature on the surface prevents undesired blue colouring of the workpiece.

Good, steady guidance

When only wood or plastics are ground, the disc must be cleaned by grinding on a sharp-edged iron tool.

Datasheets(X)

General steel construction

- Welding seam preparation and post-processing

- Derusting

- Removal of scale (in small quantities)

- Grinding of wrought ironwork (grills, railings, banisters handrails)

- Removal of excess zinc on weld seams before plastic coating

Stainless steel processing

- Pipeline construction, tank and container construction

- Apparatus construction (chemical industry)

- Plant construction, e.g. brewing and food industry

- Boat building

Aluminium processing (all non-ferrous metals)

- Special vehicles, such as silo vehicles, ambulances, fire engines etc.

- Ship-building

- Aircraft construction

Agricultural machinery

Sharpening of blades (lawn mowers, reciprocating finger bar mowers)

Body construction

- Accident repairs: Paints and filler compounds, MIG solder seams

- Special vehicle construction (lorry attachments, servicing, wearing parts for bulk material transporters)

Wood and FRP processing

Precise surfaces or edge corrections.

Diameter (Ø) | 125 mm |

Drill hole | 22.23 mm |

Grid size | 60 |

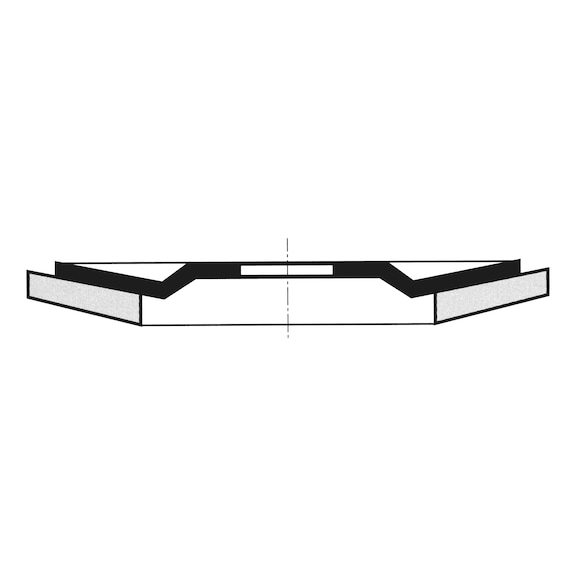

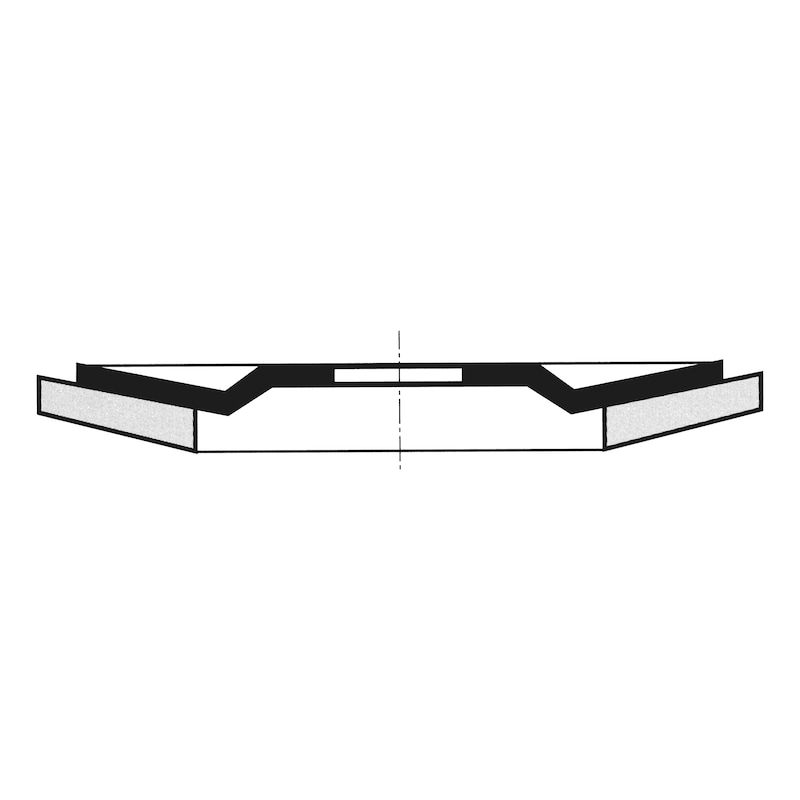

Design | Domed |

Material of carrier disc | Glass fabric |

Max. rotation speed | 12250 rpm |

Max. recommended rotation speed | 7500 rpm |

Material of abrasive medium | Zirconium conrundum |