The images are examples. For detailed information, other images and documents, please select individual articles from the following table.

Screw for AMO®-Therm Mini stand-off installation system

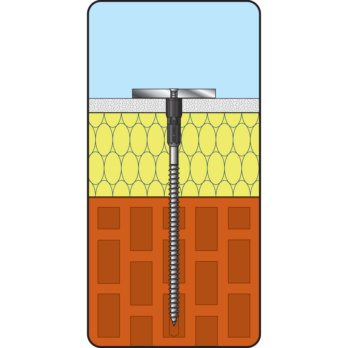

For anchor-less fastening of light to medium loads in insulated façades with thermal break. Anchoring through the insulation in masonry

Register now and access more than 125,000 products

Variants

The AMO®-Therm Mini spacer installation system consists of this screw and an adapter that is available separately

Numerous applications with just two system components

- A single screw length for insulation thicknesses from 60 to 200 mm (simply adjust the length of thread engagement depending on the insulation thickness)

- Adapter with moulded M8 and M10 female thread

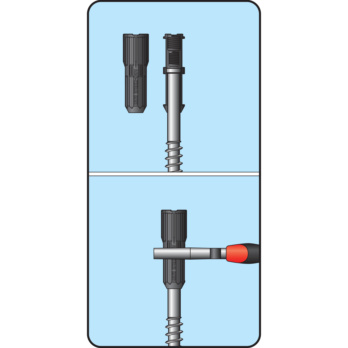

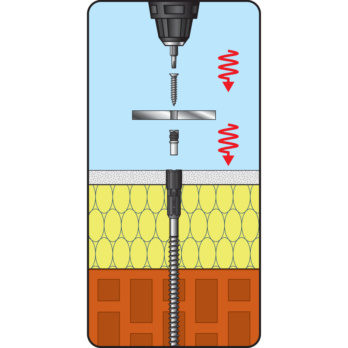

- The adapter consists of two half-shells, whereby both half-shells are clipped together centrally over the screw shaft using combination pliers. The adapter is additionally pressed together at the front and back with the combination pliers. The adapter does not sit tightly around the screw head, both elements can be rotated separately

- Connection of M6 screw and ASSY®-D plug screw (∅ 3.5–5 mm) possible with adapter insert

- Downpipe mounting with M10x45 mm threaded fitting in A2 stainless steel, collar, and sealing washer

- Fastening in masonry without thermal bridges

This screw can only be used in conjunction with the adapter for the spacer installation system AMO®-Therm Mini. A special drill bit for concrete and another for masonry are included in the assortment. Please observe the recommendations under Accessories.

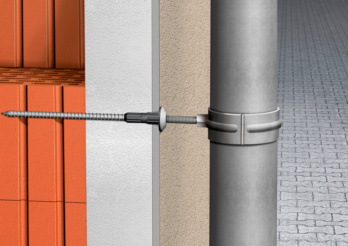

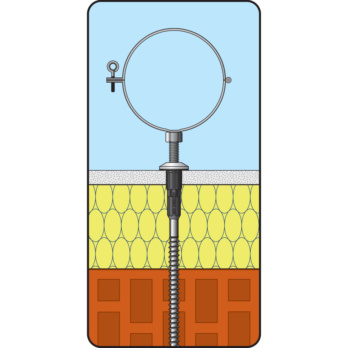

Spacer installation system AMO®-Therm Mini: Downpipe attachment in masonry

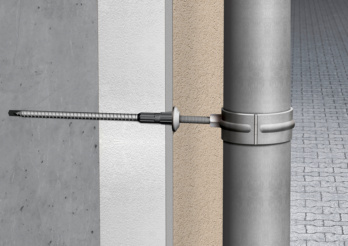

Spacer installation system AMO®-Therm Mini: Downpipe attachment in concrete

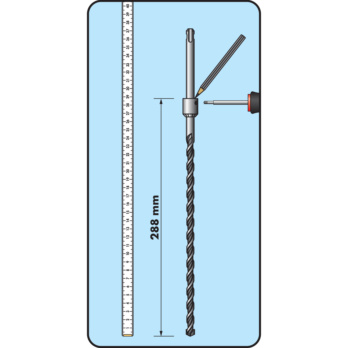

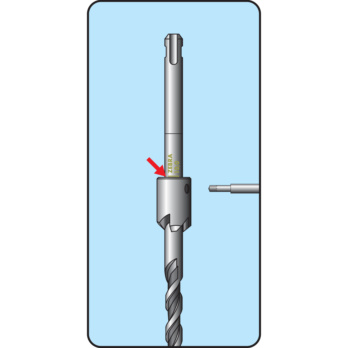

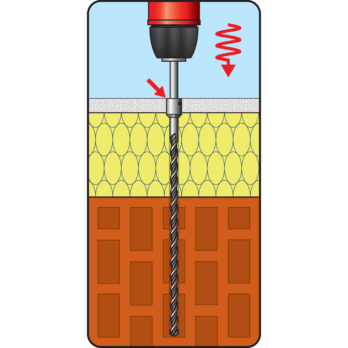

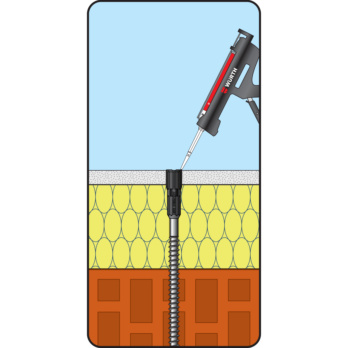

Mount the countersink on the drill bit

Observe the marking

Drilling core hole and countersink in one step. The generally required drilling depth of 288 mm is achieved when the end of the countersink is flush with the surface of the wall plaster

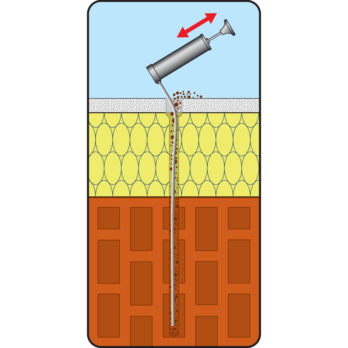

Remove drill cuttings from drill hole

The adapter offers an M8/M10 combination connection.

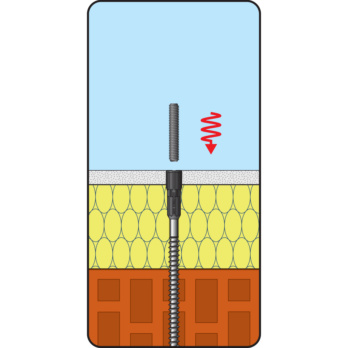

The two half-shells are clipped together centrally over the screw shaft using combination pliers. As a precaution, use the combination pliers to press the adapter together at the top and bottom. The adapter does not sit tightly around the screw head, both elements can be rotated separately

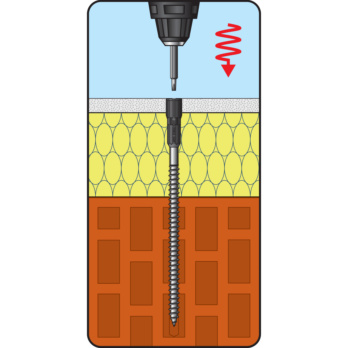

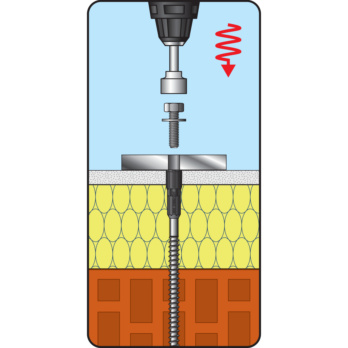

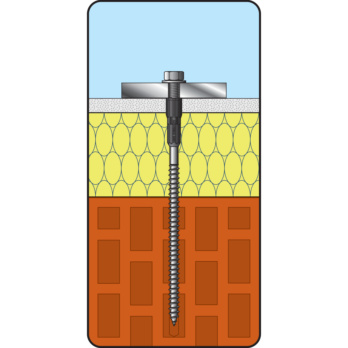

The drive is reached with a 70-mm bit, the screw is screwed into the base material flush with the surface (plaster or insulation). The adapter is then adjusted with a 1-mm protrusion. As soon as the outer bars of the adapter are able to engage in the insulation, the adapter no longer turns with the rest of the unit

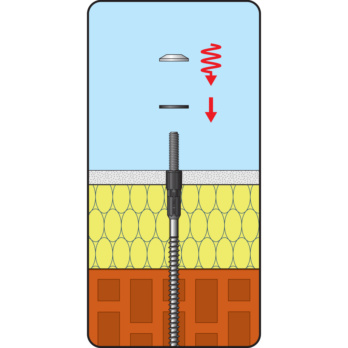

Fill the ring gap with window and façade sealant

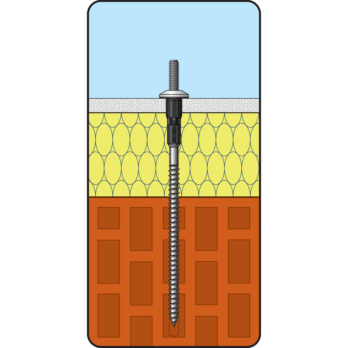

Installation of downpipe clamp: Screw threaded rod M10 flush into the adapter

Remove the adhesive film from the sealing washer and push over the threaded rod flush to the surface with the adhesive coating facing up

Screw on the collar flush

Screw on the downpipe clamp

Installing M10/M8: The attachment is fastened with a suitable screw

Screw in screw until flush

The supplied insert is screwed into the M10 thread, thus creating a mounting option for an ASSY-D® screw ∅ 4-5

Screw in screw until flush

For mounting light to medium loads (letterboxes, lamps, surveillance cameras or guttering down pipes (multiple mounting) in insulated façades with or without plaster.

Fill the ring gap between the insulation and the adapter with a suitable sealant. Window and façade sealant, art. no. 0892320010 is recommended.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!