The images are examples. For detailed information, other images and documents, please select individual articles from the following table.

Register now and access more than 125,000 products

Variants

- Material: Polypropylene

- Ageing-resistant

- Temperature-resistant

- Optimised rib system for high load-bearing capacity

- Verified compatibility with conventional glazing sealants (based on polysulphide, polyurethane and silicone)

- Ventilation channel for vapour pressure compensation (from 32 mm block width and 2 mm thickness upwards)

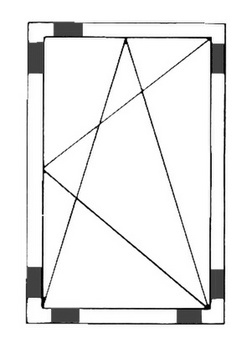

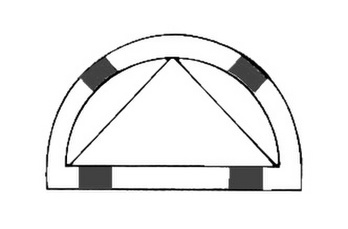

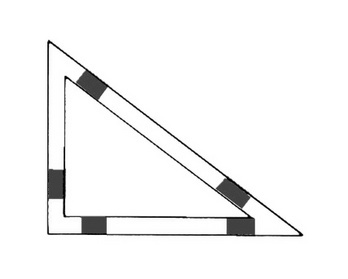

Rotor

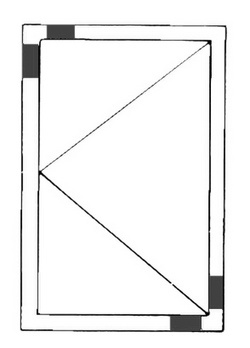

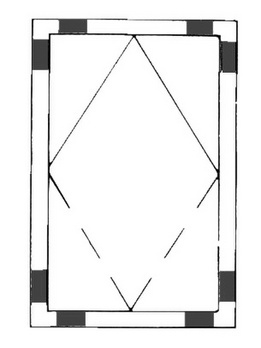

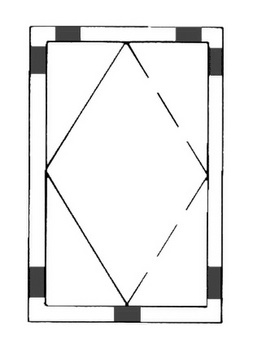

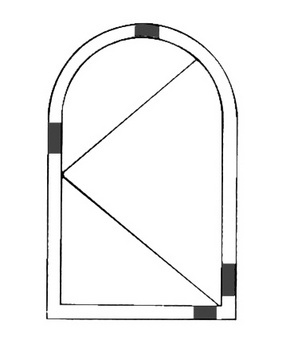

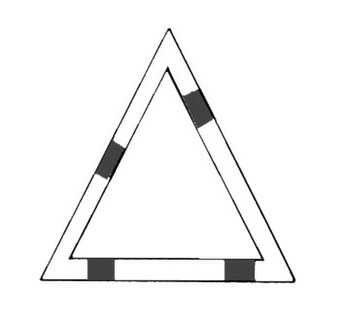

Tilt-turn sash

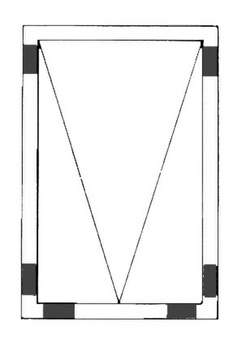

Tilt Blades

Damper blade

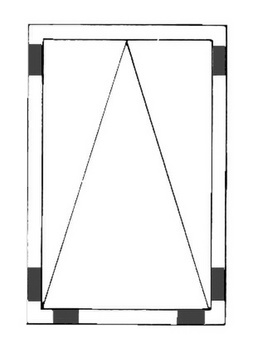

Swing Wing

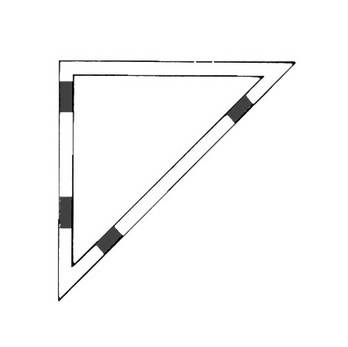

Free-Standing Glazing

Center turning blade

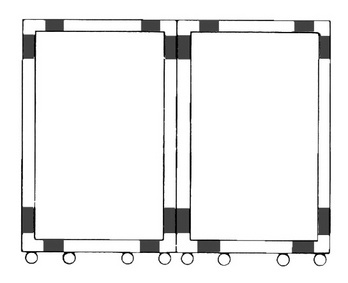

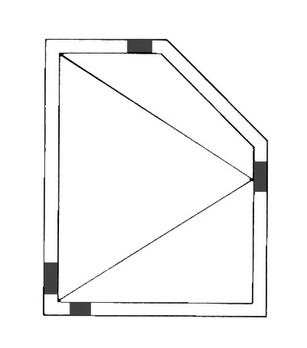

Horizontal sliding window

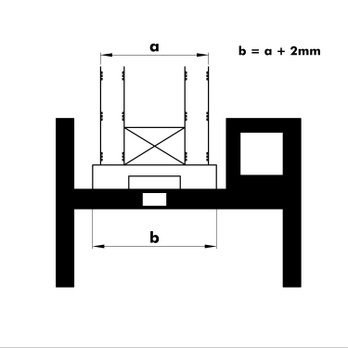

Dimensioning

The width b depends on the (window) frame system and the thickness a of the glazing unit. If there are no other regulations for specific glass products or glazing systems from glass manufacturers, the glazing blocks should be 2 mm wider than the thickness of the glazing unit.

Glazing blocks verified as compatible with cured sealants of insulating glass edge seals

- Test report 607 41481/4

- Tests carried out in line with ift directive VE 05/01 "Verified compatibility of glazing blocks" in conjunction with conventional sealants used for insulating glass edge seals based on polysulphide, polyurethane, silicone and Würth Natural Stone Sealant and Würth Glass Active Sealing Compound.

Application instructions

Glazing must be set in such a way that the glass edges are not overstrained. The glass edges must not touch the frame at any point. Installation position and number of glazing blocks should comply with glazing trade technical guideline no. 3 "Block setting glazing units".

Block alignment

Blocks should be positioned about one block length from the corners of the glazing units. The distance can be reduced to 20 mm in some cases if the risk of glass breakage is not increased by the frame and the position of the block. Blocks can be positioned about 250 mm from the corners of very wide, fixed glazing units. Glazing blocks must be positioned over a frame fastening point. The number of glazing blocks should be increased accordingly for heavy glazing units.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!