For detailed information, other images and documents, please select individual articles from the following table.

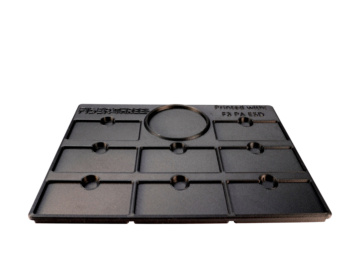

Fiberthree F3 PA ESD FFF printing material

Polyamide technical filament modified for 3D printing with additional carbon fibre filler and conductive particles

Register now and access more than 125,000 products

Variants

- The carbon fibres minimise shrinkage, which reduces the risk of warping

- The material exhibits a very high level of strength with residual impact resistance, low warping tendency and very good layer adhesion

- The good heat and media resistance make it suitable for all applications for high-strength parts which should also exhibit ESD conductivity in the printed component

- The expected resistance (surface or contact) is less than 10ꝰ Ωcm in the printed component

- Attractive matt surface finish

- Tempering at 70 °C for several hours can increase the crystallinity of the polymer

- This increases the strength and resistance of the polyamide under warm and damp conditions

Advantages

- PA 6 (modified) with ESD conductivity

- Contains carbon fibres and conductive particles

- Very high strength and low warping tendency

- Good adhesion to printbed

- Matt black finish

- 10-5 to 10-9 S/cm conductivity when printed

Application instructions

- The use of abrasion-resistant nozzles is strongly recommended

- The filament must be stored and printed in a dry environment for the best printing results

- A drying box and drying agent/desiccant are recommended

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!