For detailed information, other images and documents, please select individual articles from the following table.

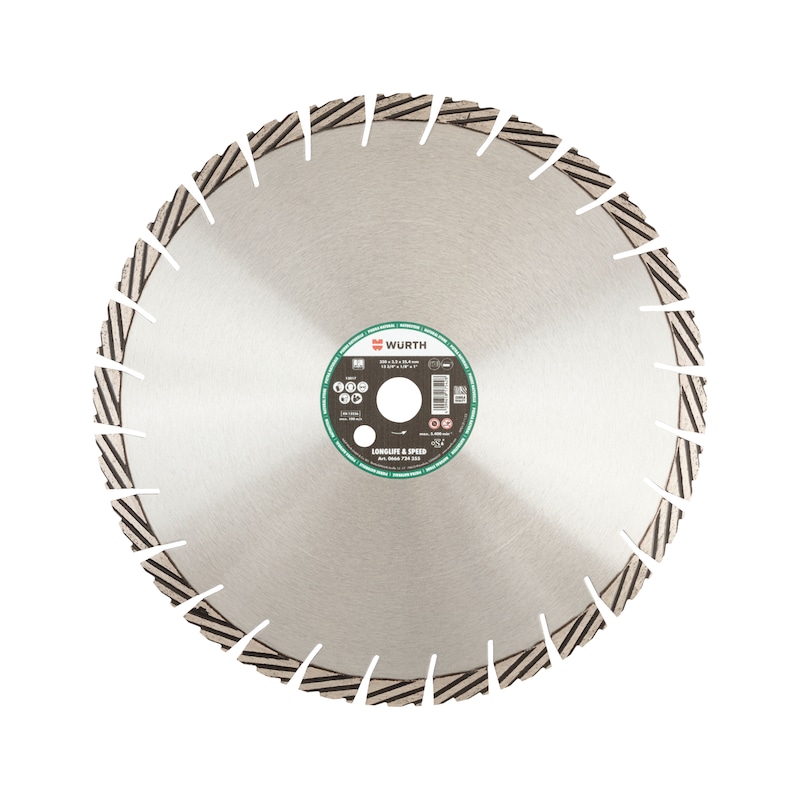

Longlife & Speed diamond cutting disc for natural stone

Diamond cutting disc with extremely long service life and very high cutting speed, specially developed for natural stone

Register now and access more than 125,000 products

Variants

Innovative cascading segment design with special milled recesses

For increased speed, improved removal of cutting dust and more effective cooling

30/25.4 mm bore design with sandwich carrier and integrated copper film

- For noise reduction by up to 15 dB

- The user's subjective perception of the noise level is reduced by half

Consistent cutting performance

Due to diamond content and enhanced bond flexibility

Extremely long service life

Thanks to 15 mm segment height

- Diamond cutting discs become dull at excessively high rotation speeds and wear too quickly at excessively low circumferential speeds

- If the cutting performance deteriorates (indicated by heavy sparking), resharpen the disc by making multiple cuts in an abrasive material, such as sandstone

- Larger workpiece cross-sections should be cut in several sections (oscillating cut)

- Work without pressure - the weight of the power tool itself is sufficient. Increased pressure causes increased wear.

- Diamond cutting discs are designed for straight cutting. Cutting curves deforms the blade and results in core cracks and segment tear-offs. Risk of injury!

- Although the tool is safe, safety goggles and protective clothing must always be worn while working

- Observe the information on the label (max. rotation speed), the restrictions of use and the safety instructions

- The direction arrow on the disc must match the direction of rotation of the power tool

- Do not use for side grinding

- Use a suitable protective cover

- Clamping must be performed only by a trained specialist (do not use force, use clamping flanges of the same size, perform a test run)

- Grinding tools that are clamped or used incorrectly or are damaged are dangerous and can cause serious injury

- Exposed aggregate concrete and other common concrete materials, clinker brick, porphyry, granite and other natural stone and hard rock

- Specially designed for gardening and landscaping. Extremely efficient cutting of granite slabs or natural stone slabs

- For dry and wet cutting

- For use on manual cutting discs, bench saws and floor saws

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!