For detailed information, other images and documents, please select individual articles from the following table.

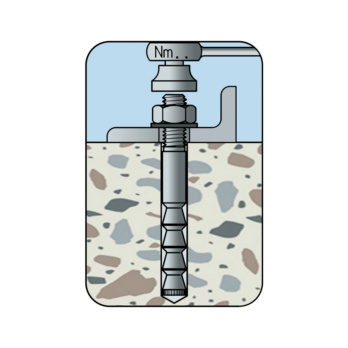

W-VIZ-A anchor rod, high corrosion resistance steel for W-VIZ/HCR injection systems (concrete)

High corrosion-resistance (HCR) steel

Register now and access more than 125,000 products

Variants

- In-place installation (M10 to M24) and pre-positioned installation (M8 to M24)

- High working loads, small spacing and edge distances

- The bonded anchor is suitable for cracked concrete (concrete tensile zone) and non-cracked concrete (concrete compressive zone)

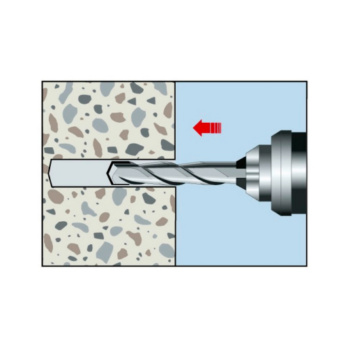

- The drill holes can be created using a hammer drill (W-VIZ M8 to M24), vacuum drill (W-VIZ M10 to M24) or diamond drill process (W-VIZ M10 to M24)

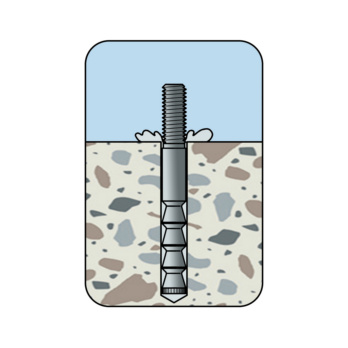

- Hardened injectable mortar largely seals off the drill hole

- Mounting with low expansion pressure allows small spacing and edge distances

- The geometry of the anchor rod allows safe follow-up expansion capability

- Mechanical drill hole cleaning: Easy handling, very good drill hole cleaning, high working loads

- Safe installation if the specified torque is applied when installing the anchor

- Force-controlled/torque-controlled expansion anchor made of highly corrosion-resistant steel

- The load is transferred via the mechanical interlocking of individual cones in the injection mortar and also via a combination of retention and frictional forces in the base material (concrete)

- European technical assessment ETA-04/0095 for fixing point option 1, cracked and non-cracked concrete, seismic performance category C1 and C2

- Fire resistance: F30, F60, F90 and F120 - exposure to fire according to DIN 4102-02: 1977-09 (uniform temperature time curve)

- Tunnel fire room curve, ZTV-ING: W-VIZ/HCR M8 to M24

Suitable injectable mortar: WIT-VIZ, WIT-VIZ Express

Drill the hole

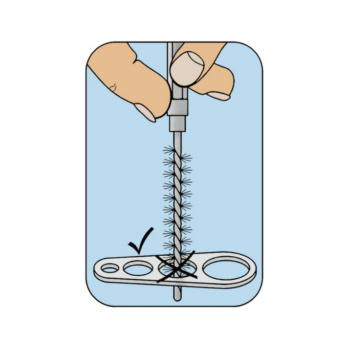

Check the cleaning brush diameter

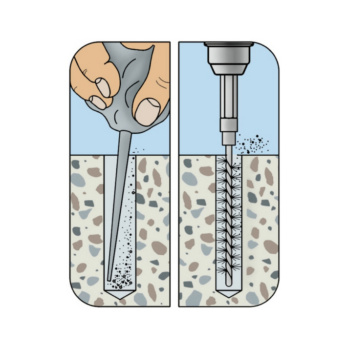

Clean drill hole (blow out twice, brush out mechanically twice, blow out twice), blow out with compressed air in case of M20 drill hole or larger.

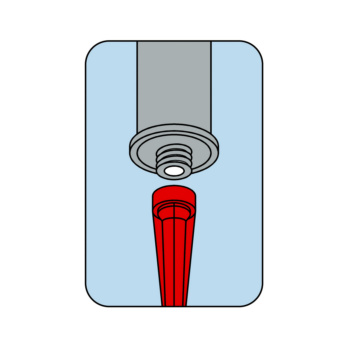

Screw mixer onto cartridge

Before use, press out approx. 10 cm cord. Do not use this initial mortar!

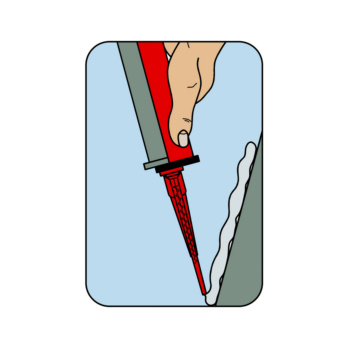

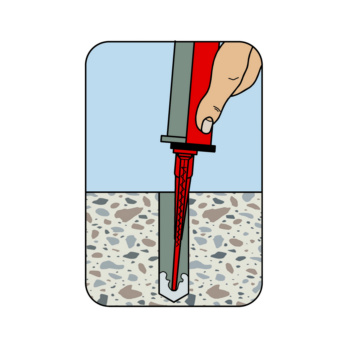

Fill injection mortar starting from base of drill hole

Press in anchor rod up to drill hole base while turning slightly

Visual check of mortar volume, embedment depth mark

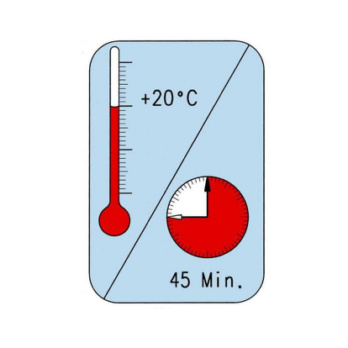

Observe the injection mortar curing time

Install component, apply installation torque

- European technical assessment ETA-04/0095 for fixing point option 1, cracked and non-cracked concrete, seismic performance category C1 and C2

- Fire resistance: F30, F60, F90 and F120 - exposure to fire according to DIN 4102-02: 1977-09 (uniform temperature time curve)

- Tunnel fire room curve, ZTV-ING: W-VIZ/HCR M8 to M24

- The anchor has a European technical assessment that approves the anchor for use in reinforced or unreinforced normal weight concrete with a concrete compressive strength of min. C20/25 and max. C50/60 in accordance with EN 206-1:2000-12

- Anchorage with European technical assessment in cracked concrete (concrete tensile zone) and non-cracked concrete (concrete compressive zone)

- Static (e.g. dead load, equipment, storage materials) or quasi-static (e.g. staircase railings) effects: M8 to M24

- Seismic effects, earthquakes (category C1 + C2): M10 to M24

- Anchor size M8 to M24: Installation in dry or wet concrete

- Anchor size M12 to M24: Installation in drill holes filled with water (exception: W-VIZ-A 75 M12 - installation in water-filled drill holes not permitted)

- For use in concrete < C20/25 and pressure-resistant natural stone (without approval)

- W-VIZ/HCR (HCR high corrosion-resistant steel) can be used in particularly aggressive conditions. These conditions include e.g. constant, repeated immersion in salt water or within the splash zone of salt water, indoor swimming pools with atmospheres containing chlorine or atmospheres with extreme chemical contamination (e.g. flue gas desulphurisation systems or road tunnels in which de-icing agents are used)

- Suitable for mounting metal structures, metal profiles, brackets, base plates, supports, staircase railings, wooden structures, beams etc.

Clean the drill hole: 2x blow out, 2x mechanical brush out, 2x blow out

If the drill hole is M20 or larger, blow out with pneumatic air using the appropriate pneumatic air nozzles

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!