For detailed information, other images and documents, please select individual articles from the following table.

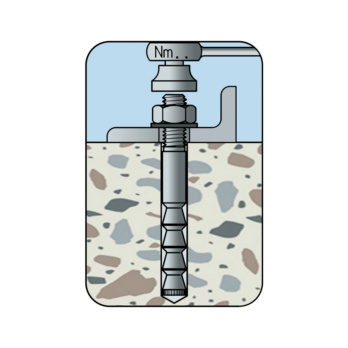

W-VIZ-A anchor rod, A4 stainless steel for W-VIZ/A4 injection systems (concrete)

Register now and access more than 125,000 products

Variants

- In-place installation (M10 to M24) and pre-positioned installation (M8 to M24)

- High loads, minimum spacing and edge distances

- The bonded anchor is suitable for cracked concrete (concrete tensile zone) and non-cracked concrete (concrete compressive zone)

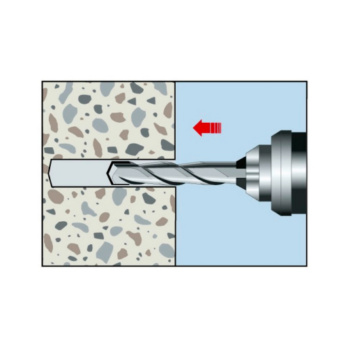

- The drill holes can be created using a hammer drill (W-VIZ M8 to M24), vacuum drill (W-VIZ M10 to M24) or diamond drill process (W-VIZ M10 to M24)

- Hardened chemical injection mortar largely seals off the drill hole

- Attachment with low expansion pressure allows minimum spacing and edge distances

- Geometry of anchor rod allows safe follow-up expansion capability

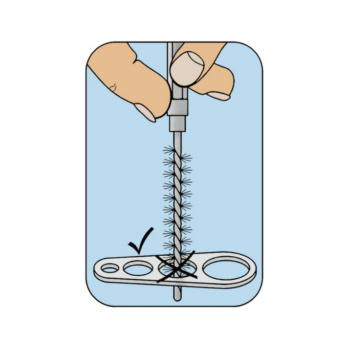

- Mechanical drill hole cleaning: Easy handling, very good drill hole cleaning, high loads

- Safe installation if the specified torque is applied when installing the anchor

- Force-controlled/torque-controlled expansion anchors made of stainless steel in sizes M8, M10, M12, M16, M20 and M24

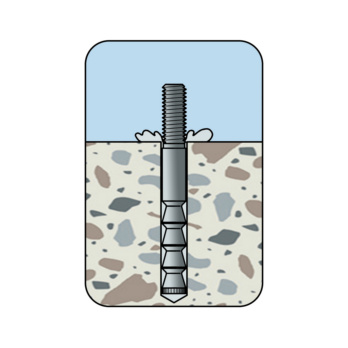

- The load is transferred via the mechanical interlocking of individual cones in the injection mortar and also via a combination of retention and frictional forces in the base material (concrete)

- European technical assessment ETA-04/0095 for fixing point option 1, cracked and non-cracked concrete, seismic performance category C1 and C2

- Fire resistance: F30, F60, F90 and F120

Suitable injectable mortar: WIT-VIZ, WIT-VIZ Express

Drill the hole

Check the cleaning brush diameter

Clean drill hole (blow out twice, brush out mechanically twice, blow out twice), blow out with compressed air in case of M20 drill hole or larger.

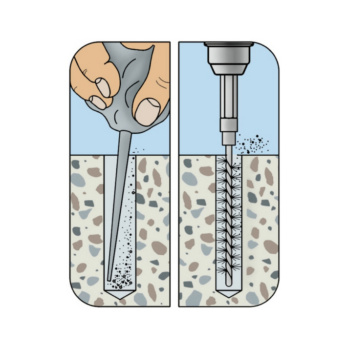

Screw mixer onto cartridge

Before use, press out approx. 10 cm cord. Do not use this initial mortar!

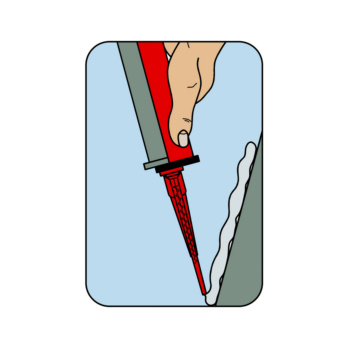

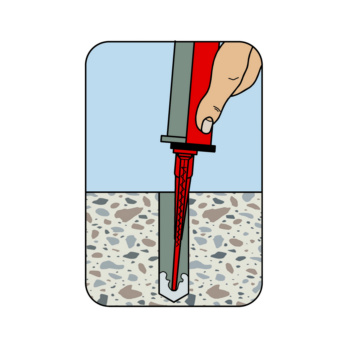

Fill injection mortar starting from base of drill hole

Press in anchor rod up to drill hole base while turning slightly

Visual check of mortar volume, embedment depth mark

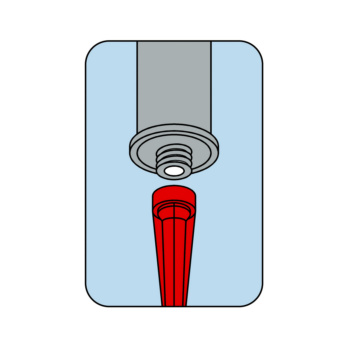

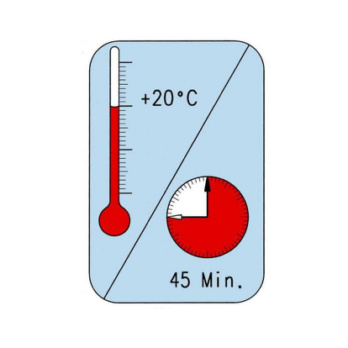

Observe the injection mortar curing time

Install component, apply installation torque

- European technical assessment ETA-04/0095 for fixing point option 1, cracked and non-cracked concrete, seismic performance category C1 and C2

- Fire resistance: F30, F60, F90 and F120

- The anchor has a European technical assessment for use in reinforced or unreinforced normal weight concrete with a concrete compressive strength of min. C20/25 and max. C50/60 in accordance with EN 206-1:2000-12

- Anchorage with European technical assessment in cracked concrete (concrete tensile zone) and non-cracked concrete (concrete compressive zone)

- Static (e.g. dead load, equipment, storage materials) or quasi-static (e.g. staircase railings) actions: M8 to M24

- Seismic effects, earthquakes (category C1 + C2): M10 to M24

- Anchor size M8 to M24: Installation in dry or wet concrete

- Anchor sizes M12 to M24: installation in water-filled drill holes (exception: W-VIZ-A 75 M12 - installation in water-filled drill holes not permitted)

- For use in concrete < C20/25 and pressure-resistant natural stone (without approval)

- W-VIZ/A4 (stainless steel A4) can be used in dry indoor areas, outdoors (including in industrial atmospheres and coastal areas) or in wet rooms

- Suitable for fastening metal structures, metal profiles, brackets, base plates, supports, railings, wooden structures, beams etc.

Clean the drill hole: 2x blow-out, 2x mechanical brush-out, 2x blow-out

If the drill hole is M20 or larger, blow out with pneumatic air using the appropriate pneumatic air nozzles

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!