For detailed information, other images and documents, please select individual articles from the following table.

ASSY® 4 CS fittings screw Steel zinc plated full thread countersunk head

Full-thread screw with countersunk head for fastening fittings or cabinet connectors in wood or wooden panels in indoor dry or sheltered areas

Register now and access more than 125,000 products

Variants

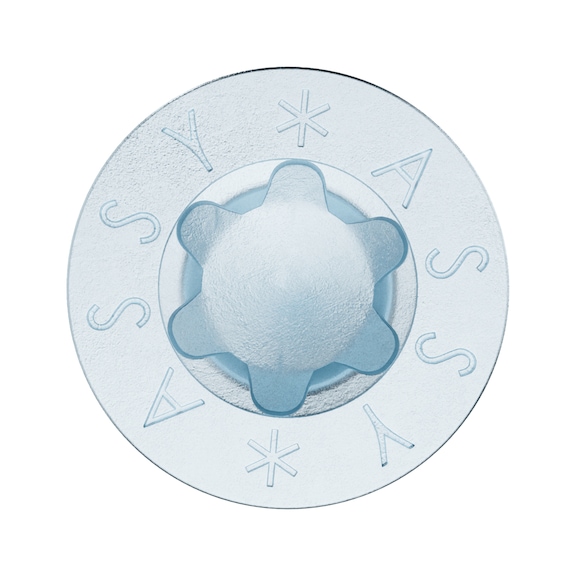

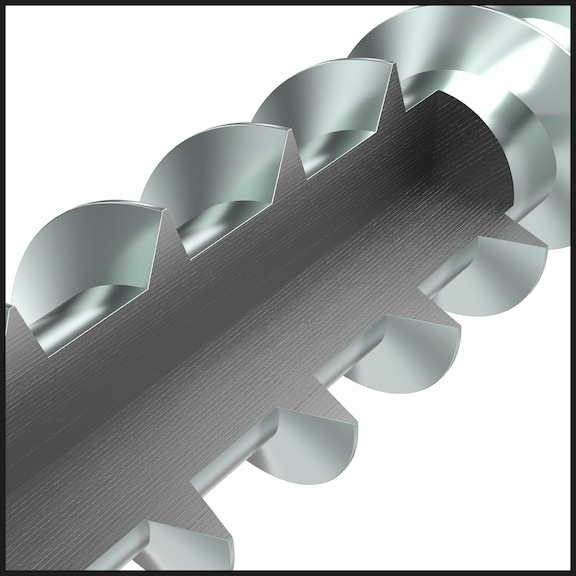

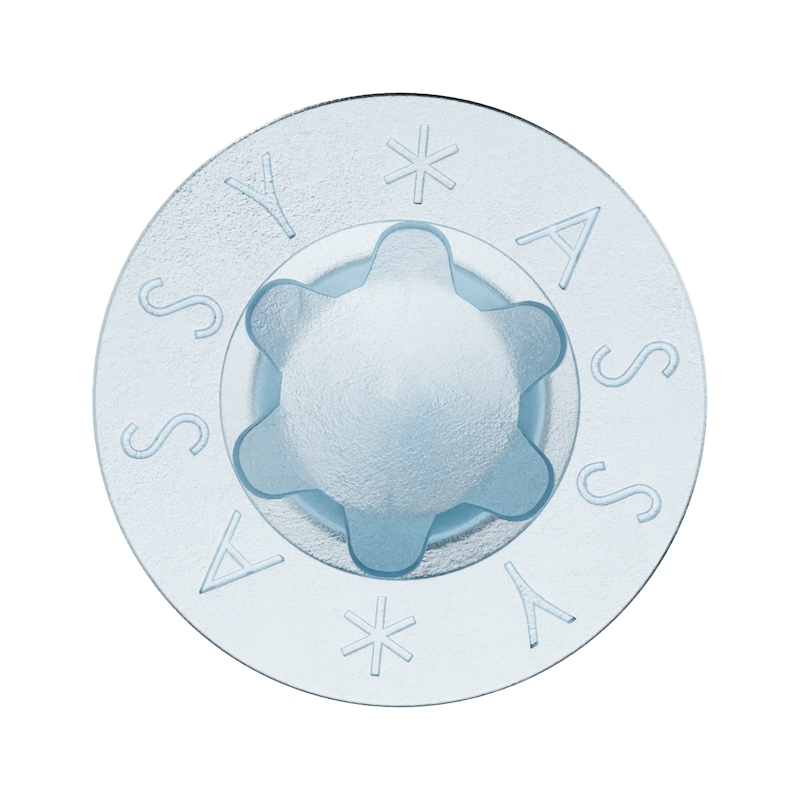

Ideal power transmission thanks to RW recess

- More power due to larger contact area at the bit

- More stability, one-handed working and precise positioning due to the tight-fit recess and perfect fit of the bit

- Fewer bit changes, one bit for many screw diameters

- Compatibility with previous AW drive

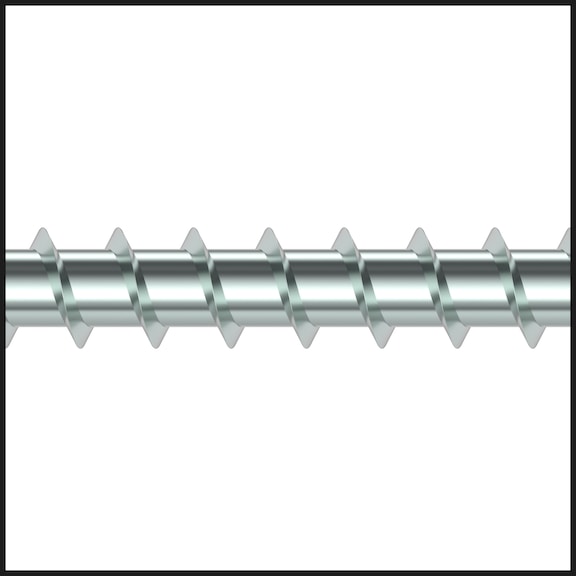

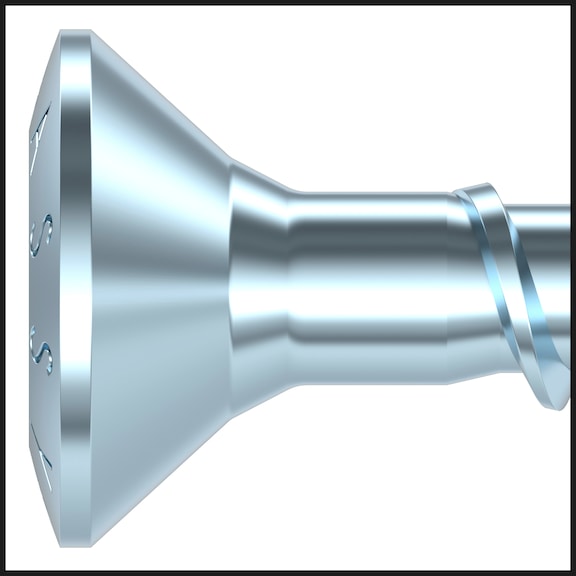

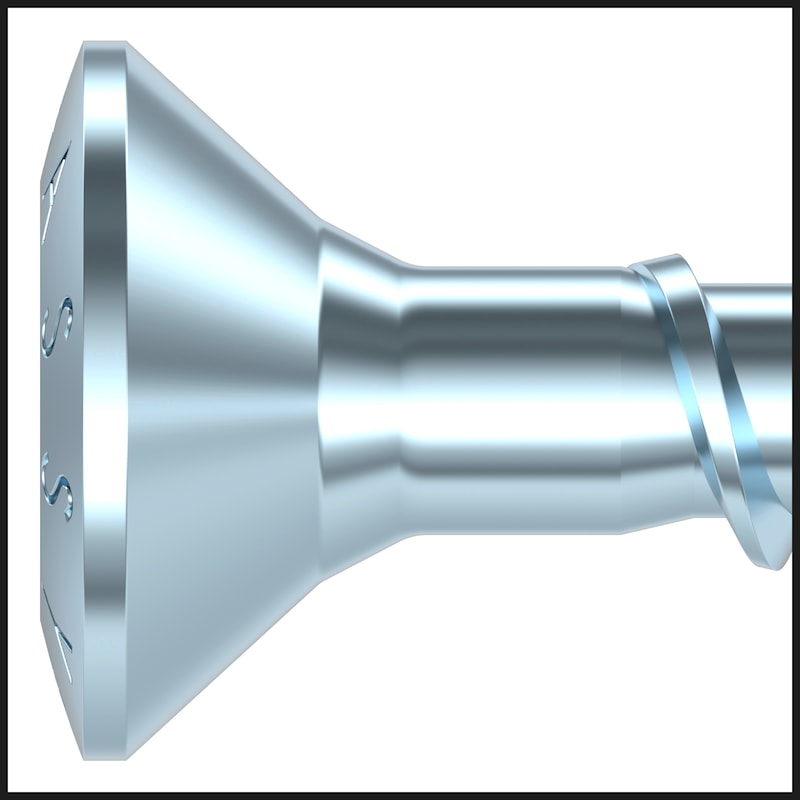

Positive connection to metal fittings or in wooden products with high bulk density

- For fitting connection with full thread steel screws

- Perfect fit of 90° head in fittings with metal countersinks

- Tight joint without head milling due to lack of milling elements below the head

- The head is countersunk by pressing

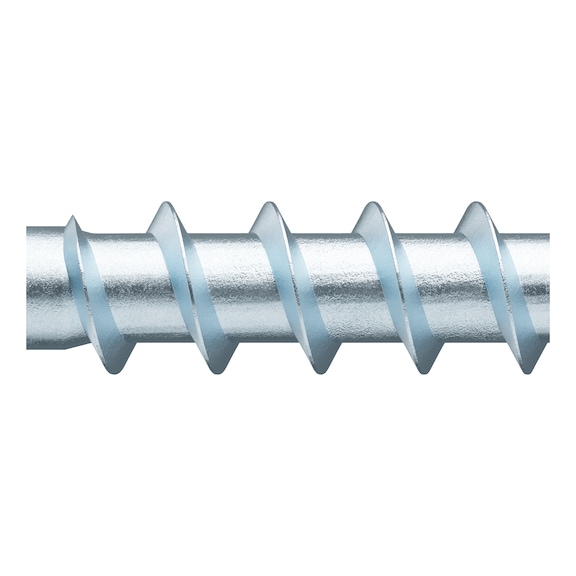

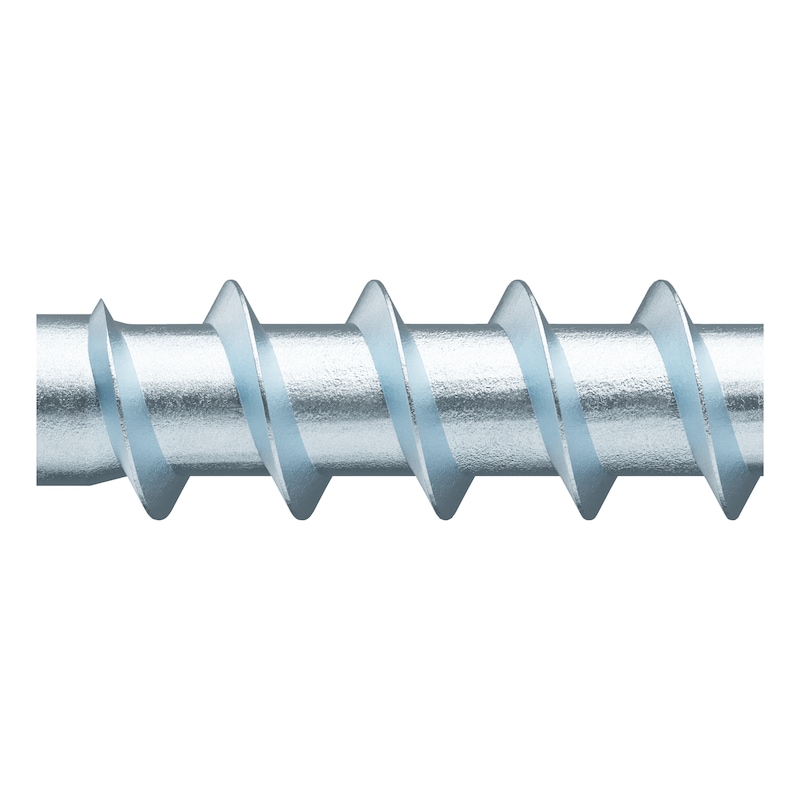

Maximum overtightening safety with high feed performance

- Higher power transmission in hardwoods due to reinforced, asymmetrical thread flank geometry of the coarse thread

- Better anchorage thanks to higher thread flanks

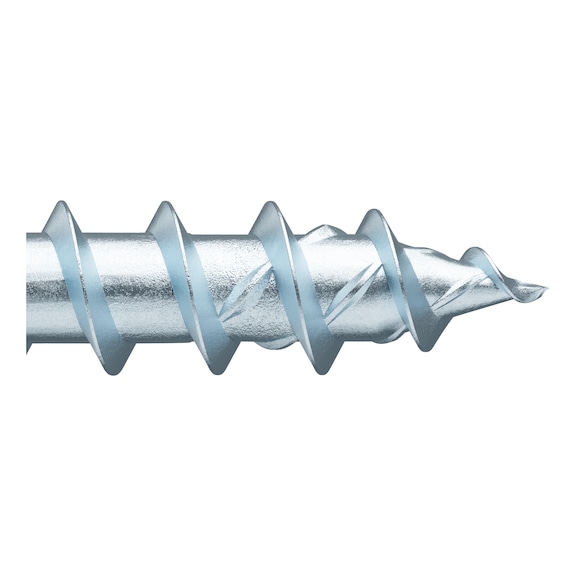

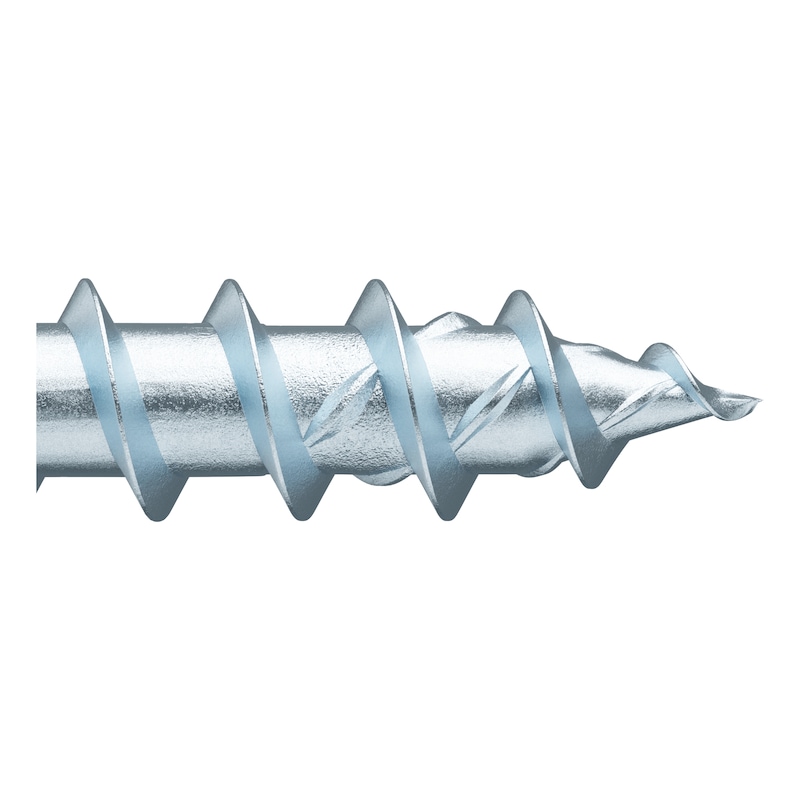

Smooth thread start ensures optimised recessing and biting of the screw

- Reduced splitting thanks to displacement effect of the dome-shaped milling elements in the tip

- Reduced-friction thread rotation allows reduction of the screw-in force that is applied

- We recommend using the Würth software or the corresponding design aids for planning and dimensioning your assembly. Use the Würth timber construction software for dimensioning of ASSY screws from a diameter of 5 mm

- Do not use the screw in applications with direct exposure to the elements or in humid rooms with atmospheres containing chlorine gas. If used outdoors and in rooms that are constantly exposed to high humidity, please use ASSY 4 A2 or A4 stainless steel screws and, if atmosphere contains chlorine, HCR stainless steel screws

- ASSY 4, ASSYplus 4 and ASSYplus 4 FT chipboard screws are optimised for use in wood and wood materials. For applications in plastic anchors where load capacity can also be reduced, use only screws without an optimised thread tip (tip with milling ribs, drill tip, self-clearing groove etc.), such as the ASSY D screws with countersunk head or pan head

ETA-11/0190 approved

The requirements of the European Technical Approval (ETA) must be observed

For steel-wood connections designed for tensile forces

The full thread starting immediately below the head allows for e.g. fitting-wood or sheet material-wood connections designed for tensile forces with high load-bearing capacity. Greater screw pull-out force is achieved by the maximum thread length.

For applications in utilisation class 1 and utilisation class 2 (from ∅ > 4 mm)

- High-quality surface protection, zinc, blue-passivated chromium(VI)-free 5 µm layer thickness

- Suitable for use in utilisation class 1 (interior) and from a ∅ > 4 mm in utilisation class 2 (covered outdoor area) according to EN 1995-1-1:2010-12 + DIN SPEC 1052-100:2013-08

- ASSY screws are approved for quasi-static loads

- For optimum use of the screw, the right-size RW bit must be used

- Full-thread screws are suitable for secure mounting of fittings or thin materials. The screw length to be selected should be less than the plate thickness of substrate the screw is to be driven in

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!