For detailed information, other images and documents, please select individual articles from the following table.

2C cartridge foam PURlogic® Sprint

2C cartridge foam for fast and easy door frame installation, non-stick after just 3 minutes

- Chemical basis: Mix of polyether polyols, diphenylmethane-4, 4'-diisocyanate

- Colour: Brown beige, similar to RAL 1011

- Smell/fragrance: Characteristic

- Moulded density: 50 kg/m³

- Conditions for moulded density: foamed into joints, tested in accordance with Würth test methods

- Cell structure: Medium - fine

- Cell structure conditions: tested in accordance with Würth test methods

- Working life: 1 min

- Tack-free after: 3 min

- Conditions for being tack-free: tested in accordance with Würth test methods

- Can be cut after: 7 min

- Conditions for ability to cut: tested in accordance with Würth test methods

- Full resilience: 30 min

- Conditions for full resilience: tested in accordance with Würth test methods

- Final spreading possible after: 20 min

- Conditions for final spreading: at 20°C and 50% relative humidity, tested in accordance with Würth test methods

- Min./max. processing temperature: 10 to 25 °C

- Min./max. ambient processing temperature: 10 to 25 °C

- Min./max. surface processing temperature: 10 to 25 °C

- Min./max. processing temperature for can: 10 to 25 °C

- Min./max. temperature resistance: -30 to 80 °C

- Max. short-term temperature resistance: 100 °C

- Compression strength: 8 N/cm²

- Compression strength conditions: based on DIN 53421, at 10% compression

- Min. combined tension and shear resistance: 9 N/cm²

- Conditions for combined tension and shear resistance: in accordance with DIN 53427

- Min. tensile strength: 10 N/cm²

- Conditions for tensile strength: in accordance with DIN 53455

- Elongation at break: 19 %

- Elongation at break conditions: in accordance with DIN 53455

- Yield (volume) approx.: 5 l

- Conditions for yield: Tested in accordance with Würth test methods

- Contents: 210 ml

- Weight of content: 254.1 g

- Building material class: B2 - Normally inflammable

- Building material class conditions: in accordance with DIN 4102

- Resistance against: Aging

- Shelf life from production: 9 Month

- Conditions to maintain shelf life from production: cool and dry storage area below 25°C

- show more ... show less ...

Register now and access more than 125,000 products

Variants

Very quick to reach final strength

Reduces expansion time to 20 minutes. This saves time and costs

Good adhesive properties

Adheres well to various wall joint and frame materials

Dimensionally stable foam

- No pressing during and after the hardening phase

- < 5% dimensional change, tested in accordance with ift directive from the ift Rosenheim Institute in Germany.

For installing wooden and steel door frames

Tested in accordance with ift directive from ift Rosenheim in Germany.

General test certificate from construction authorities

Corresponds to building material class B2 in accordance with DIN 4102, Part 1, tested by MPA Hanover in Germany.

High compressive load

Uniform, fine-celled foam structure

High degree of emptying

Resistant to ageing

Adheres to concrete, stone, hard PVC, metal and wood. Does not adhere to polyethylene, silicone, PTFE and grease. Primer should be used for porous and absorbent substrates. Store upright cartridges in a cool, dry and frost-protected place. Protect from heating up to over +30°C.

At higher temperatures, the storage time is reduced.

One cartridge is sufficient for 6 mounting points, this is the quantity for a door frame, step or window sill of size 1000 mm x 300 mm. Immediately remove any fresh flecks of foam with PURlogic® Clean. Hardened foam can only be removed mechanically.

The usage instructions are recommendations based on the tests we have conducted and our experience; carry out your own tests before each application. Due to the large number of applications and storage and processing conditions, we do not assume any liability for a specific application result. Insofar as our free customer service provides technical information or acts as an advisory service, no responsibility is assumed by this service except where the advice or information given falls within the scope of our specified, contractually agreed service or the advisor was acting deliberately. We guarantee consistent quality of our products. We reserve the right to make technical changes and further develop products.

For high-quality and secure installation of wooden and steel door frames, steps in staircases and window sills (lining must be used to protect against excessive compressive load). Sand beige colour provides visual confirmation of installation. Adheres to concrete, stone, hard PVC, metal and wood

Align door frames using installation aids:

Door frames and masonry must be load-bearing, clean and free from oils, grease and dust.

Insert the enclosed cardboard strips at the mounting points. Also use extension tube for narrow and deep joints. The mixing tube should be removed after using the foam or when you need to interrupt work. Immediately remove fresh splashes of foam with PURlogic® Clean, art. no. 0892 160. Pretreat plaster and aerated concrete with primer.

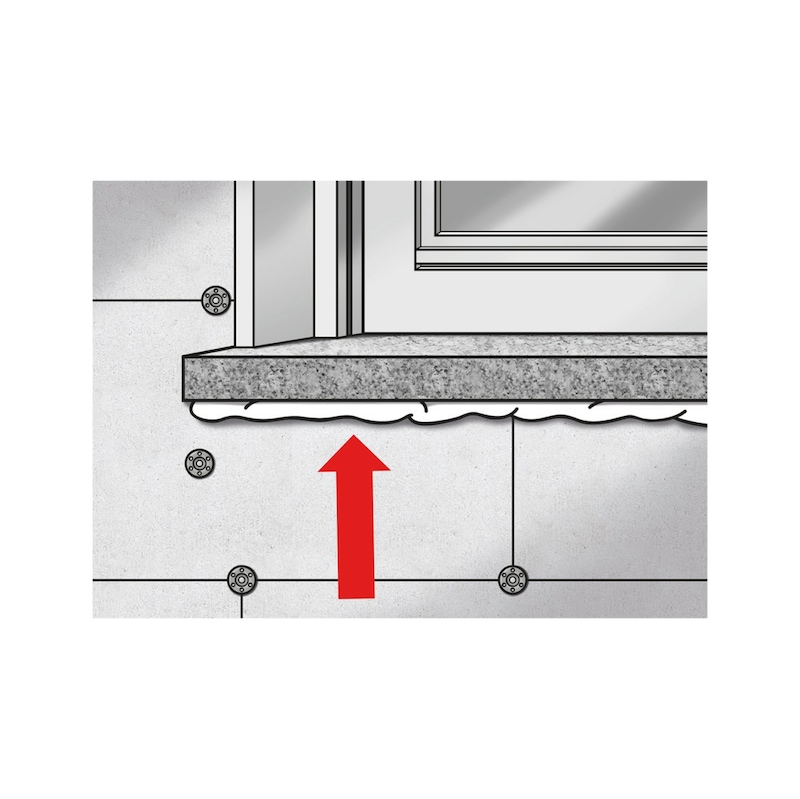

Bonding stairs:

Align components such as steps, door sills or window sills to spacers. The spacer is designed to produce an expansion joint of 5-15 mm. It is possible to apply adhesive in two ways, depending on the component size and the conditions:

- 1 Remove the component already aligned. Apply adhesive strands lengthways or crosswise at a spacing of 8-10 cm. Re-position the component immediately on the spacer. Use 2 weights per 15 kg for each spacer.

- Insert the adhesive strands into the expansion joint between the component and surface lengthways or crosswise at a spacing of 8-10 cm. For instance components such as steps, window sills or door sills, use 2 weights per 15 kg per spacer.

- Hardened expansion adhesive can be cut after 8-10 minutes.

Services und Systeme rund ums Produkt

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!