Hot melt adhesive 101

Hot melt adhesive 101

MLTADH-101-200G

Art.-no. 0890100050

EAN 4038898386223

price per selected packing unit | Individual prices for customers after login

Register now and access more than 125,000 products

- Good thermostability

- Waterproof and resistant to ageing

- Good resistance to PVC softeners

- Slightly tacky

Polyamides in balance with air humidity. The moisture absorbed can cause foaming (vapour formation) when melting polyamides. We recommend resealing the packaging well after each removal, and if necessary to dry the hot melt adhesive for 48 hours at approx. 50°C prior to processing.

Heat occurring during storage (e.g. due to solar radiation) must be avoided due to the changes to the outer shape of the hot melt adhesive this can cause.

The usage instructions are recommendations based on the tests we have conducted and on our experience; carry out your own tests before each application. Due to the large number of applications and storage and processing conditions, we do not assume any liability for a specific application result. Insofar as our free customer service provides technical information or acts as an advisory service, no responsibility is assumed by this service except where the advice or information given falls within the scope of our specified, contractually agreed service or the advisor was acting with deliberate intent. We guarantee the consistent quality of our products. We reserve the right to make technical changes and further develop products. Please observe the technical data sheet!

Datasheets(X)

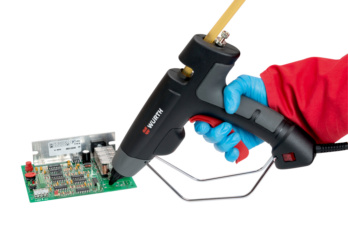

Ideal for the automotive industry for effective dent removal on different materials and surfaces by affixing pulling tabs. Also perfect for securing components and coil wires in the electrical industry.

The adhesive surfaces must be free from dust, dirt, moisture, grease and release agents. Softeners in plastics and paints can impair the durability of the adhesive. Apply the hot melt adhesive as a spot, film or bead and immediately press the parts together. Briefly applying pressure increases the strength.

Dent removal with dent lifter set:

- 1. Clean the dent with a suitable cleaner

- 2. Apply hot melt adhesive in the centre of the suitable adapter.

- 3. Affix adapter at deepest point and if necessary cool with pneumatic air.

- 4. Hook slide hammer or PinPuller into the adapter and reshape the dent.

- 5. After removing the dent, use a plastic wedge to slightly lift the hot-melt adhesive at a certain point. Spray adhesive remover spray (art. no. 0893 141) into the gap and allow to take effect.

- The adhesive remover spreads into the gaps and loosens the adhesive residue from the surface.

- 6. The adhesive residue is removed from the surface in one piece in a matter of seconds.

If necessary, remove any residual adhesive residue with the pre-cleaner (art. no. 0893 200 1).

Weight of content | 200 g |

Chemical basis | Polyamide |

Colour | Yellow |

Length | 200 mm |

Diameter | 12 mm |

Density/conditions | 1 g/cm³ / at 20°C |

Viscosity | 3500 mPas |

Softening point | 140 °C |

Min./max. open time | 20-60 s |

Min./max. processing temperature | 180 to 210 °C |

Shelf life from production | 18 Month |

Silicone-free | Yes |

Solvent-free | Yes |

Number of pieces | 10 PCS |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!