HPC end mill Speedcut 4.0-ultra hard steel 50-65 HRC, extra-long XL, four cutting edges, uneven angle of twist gradient

End mill SC 4.0 50-65HRC WN-XL 50° Vario DURALDUR

ENDMIL-HPC-4.0-WN-XL-65HRC-FG-HA-D20

Art.-no. 5443316030

EAN 4065746569033

price per selected packing unit | Individual prices for customers after login

Register now and access more than 125,000 products

Datasheets(X)

| |

Product code | 8797 |

Material to be processed | Hard and tough material |

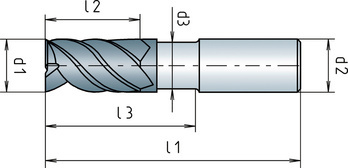

Diameter (d1) | 20.0 mm |

Shank diameter (d2) | 20.0 mm |

Clearance diameter (d3) | 19.5 mm |

Standards | CS |

Construction length | Extra long |

Shank style | Cylindrical DIN 6535-HA |

Cutting material | SC |

Surface | DUALDUR |

Coolant supply | External |

Twist angle | 50° Vario |

Length (l1) | 124 mm |

Cutting edge length (l2) | 38 mm |

Clearance length (l3) | 70 mm |

Number of cutting edges (Z) | 4 PCS |

Corner chamfer | 0.10 mm |

Tolerance of cutting edge diameter | e8 |

Tolerance of shank diameter | h6 |

Material of sub-group | Steels > 45 HRC, Nitriding steels < 1300 N/mm², Grey cast iron, Malleable cast iron, Alloyed tempering steels < 1000 N/mm² |

| Key |

| L = air |

| E = emulsion |

| vc = cutting speed [m/min] |

| fz = feed per tooth [mm/t] |

| ae cutting thickness (radial) = 0.015xd1 |

| ap cutting thickness (axial) = 1.5xd1 |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| Cutting values for finishing | |||||

| For dia. 20 | |||||

| Material designation | Tensile strength | Cooling | vc | fz | |

| Dia. 20 | |||||

| min. | max. | ||||

| Steels | |||||

| High-speed steels | < 1,300 N/mm² | E | 128 | 0,068 | 0,101 |

| Tool steels | < 1,300 N/mm² | E | 186 | 0,068 | 0,101 |

| Stainless steels | |||||

| Hardened steels | 40-48 HRC | L | 62 | 0,038 | 0,058 |

| Hardened steels | 45-55 HRC | L | 50 | 0,034 | 0,050 |

| Hardened steels | 55-60 HRC | L | 50 | 0,034 | 0,050 |

| Hardened steels | 60-65 HRC | L | 33 | 0,026 | 0,038 |

| Cast metals | |||||

| Cast iron, lamellar graphite | < 180 HB | L + E | 186 | 0,101 | 0,152 |

| Cast iron, lamellar graphite | > 260 HB | L + E | 149 | 0,101 | 0,152 |

| Nodular graphite, malleable iron | > 260 HB | L + E | 145 | 0,101 | 0,152 |

| Cutting values for finishing | |||||||||||

| For dia. 10-16 | |||||||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||||||

| Dia. 10 | Dia. 12 | Dia. 14 | Dia. 16 | ||||||||

| min. | max. | min. | max. | min. | max. | min. | max. | ||||

| Steels | |||||||||||

| High-speed steels | < 1,300 N/mm² | E | 128 | 0,033 | 0,050 | 0,042 | 0,063 | 0,044 | 0,066 | 0,056 | 0,084 |

| Tool steels | < 1,300 N/mm² | E | 186 | 0,033 | 0,050 | 0,042 | 0,063 | 0,044 | 0,066 | 0,056 | 0,084 |

| Stainless steels | |||||||||||

| Hardened steels | 40-48 HRC | L | 62 | 0,019 | 0,029 | 0,025 | 0,037 | 0,028 | 0,042 | 0,031 | 0,047 |

| Hardened steels | 45-55 HRC | L | 50 | 0,017 | 0,025 | 0,022 | 0,034 | 0,025 | 0,037 | 0,028 | 0,042 |

| Hardened steels | 55-60 HRC | L | 50 | 0,017 | 0,025 | 0,022 | 0,034 | 0,025 | 0,037 | 0,028 | 0,042 |

| Hardened steels | 60-65 HRC | L | 33 | 0,012 | 0,018 | 0,014 | 0,022 | 0,019 | 0,029 | 0,022 | 0,032 |

| Cast metals | |||||||||||

| Cast iron, lamellar graphite | < 180 HB | L + E | 186 | 0,047 | 0,071 | 0,057 | 0,086 | 0,068 | 0,103 | 0,083 | 0,125 |

| Cast iron, lamellar graphite | > 260 HB | L + E | 149 | 0,047 | 0,071 | 0,057 | 0,086 | 0,068 | 0,103 | 0,083 | 0,125 |

| Nodular graphite, malleable iron | > 260 HB | L + E | 145 | 0,047 | 0,071 | 0,057 | 0,086 | 0,068 | 0,103 | 0,083 | 0,125 |

| Cutting values for roughing | |||||||||||

| For dia. 4-8 | |||||||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||||||

| Dia. 4 | Dia. 5 | Dia. 6 | Dia. 8 | ||||||||

| min. | max. | min. | max. | min. | max. | min. | max. | ||||

| Steels | |||||||||||

| High-speed steels | < 1,300 N/mm² | E | 112 | 0,014 | 0,022 | 0,020 | 0,030 | 0,024 | 0,036 | 0,032 | 0,048 |

| Tool steels | < 1,300 N/mm² | E | 180 | 0,014 | 0,022 | 0,020 | 0,030 | 0,024 | 0,036 | 0,032 | 0,048 |

| Stainless steels | |||||||||||

| Hardened steels | 40-48 HRC | L | 60 | 0,016 | 0,024 | 0,020 | 0,030 | 0,022 | 0,034 | 0,028 | 0,044 |

| Hardened steels | 45-55 HRC | L | 48 | 0,014 | 0,022 | 0,018 | 0,028 | 0,020 | 0,032 | 0,026 | 0,038 |

| Hardened steels | 55-60 HRC | L | 48 | 0,014 | 0,022 | 0,018 | 0,028 | 0,020 | 0,032 | 0,026 | 0,038 |

| Hardened steels | 60-65 HRC | L | 32 | 0,010 | 0,014 | 0,012 | 0,020 | 0,014 | 0,022 | 0,020 | 0,028 |

| Cast metals | |||||||||||

| Cast iron, lamellar graphite | < 180 HB | L + E | 180 | 0,020 | 0,030 | 0,028 | 0,042 | 0,033 | 0,049 | 0,044 | 0,066 |

| Cast iron, lamellar graphite | > 260 HB | L + E | 144 | 0,020 | 0,030 | 0,026 | 0,040 | 0,031 | 0,047 | 0,038 | 0,056 |

| Nodular graphite, malleable iron | > 260 HB | L + E | 140 | 0,020 | 0,030 | 0,026 | 0,040 | 0,031 | 0,047 | 0,038 | 0,056 |

| Cutting values for finishing | |||||||||||

| For dia. 4-8 | |||||||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||||||

| Dia. 4 | Dia. 5 | Dia. 6 | Dia. 8 | ||||||||

| min. | max. | min. | max. | min. | max. | min. | max. | ||||

| Steels | |||||||||||

| High-speed steels | < 1,300 N/mm² | E | 128 | 0,011 | 0,017 | 0,015 | 0,023 | 0,018 | 0,027 | 0,024 | 0,036 |

| Tool steels | < 1,300 N/mm² | E | 186 | 0,011 | 0,017 | 0,015 | 0,023 | 0,018 | 0,027 | 0,024 | 0,036 |

| Stainless steels | |||||||||||

| Hardened steels | 40-48 HRC | L | 62 | 0,008 | 0,012 | 0,010 | 0,015 | 0,011 | 0,017 | 0,014 | 0,022 |

| Hardened steels | 45-55 HRC | L | 50 | 0,007 | 0,011 | 0,009 | 0,014 | 0,010 | 0,016 | 0,013 | 0,019 |

| Hardened steels | 55-60 HRC | L | 50 | 0,007 | 0,011 | 0,009 | 0,014 | 0,010 | 0,016 | 0,013 | 0,019 |

| Hardened steels | 60-65 HRC | L | 33 | 0,005 | 0,007 | 0,006 | 0,010 | 0,007 | 0,011 | 0,010 | 0,014 |

| Cast metals | |||||||||||

| Cast iron, lamellar graphite | < 180 HB | L + E | 186 | 0,015 | 0,023 | 0,021 | 0,032 | 0,025 | 0,037 | 0,033 | 0,050 |

| Cast iron, lamellar graphite | > 260 HB | L + E | 149 | 0,015 | 0,023 | 0,021 | 0,032 | 0,025 | 0,037 | 0,033 | 0,050 |

| Nodular graphite, malleable iron | > 260 HB | L + E | 145 | 0,015 | 0,023 | 0,021 | 0,032 | 0,025 | 0,037 | 0,033 | 0,050 |

| Key |

| L = air |

| E = emulsion |

| vc = cutting speed [m/min] |

| fz = feed per tooth [mm/t] |

| ae cutting thickness (radial) = 0.1-0.3xd1 |

| ap cutting thickness (axial) = 1xd1 |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| Cutting values for roughing | |||||

| For dia. 20 | |||||

| Material designation | Tensile strength | Cooling | vc | fz | |

| Dia. 20 | |||||

| min. | max. | ||||

| Steels | |||||

| High-speed steels | < 1,300 N/mm² | E | 112 | 0,090 | 0,134 |

| Tool steels | < 1,300 N/mm² | E | 180 | 0,090 | 0,134 |

| Stainless steels | |||||

| Hardened steels | 40-48 HRC | L | 60 | 0,076 | 0,116 |

| Hardened steels | 45-55 HRC | L | 48 | 0,068 | 0,100 |

| Hardened steels | 55-60 HRC | L | 48 | 0,068 | 0,100 |

| Hardened steels | 60-65 HRC | L | 32 | 0,052 | 0,076 |

| Cast metals | |||||

| Cast iron, lamellar graphite | < 180 HB | L + E | 180 | 0,135 | 0,203 |

| Cast iron, lamellar graphite | > 260 HB | L + E | 144 | 0,103 | 0,155 |

| Nodular graphite, malleable iron | > 260 HB | L + E | 140 | 0,103 | 0,155 |

| Cutting values for roughing | |||||||||||

| For dia. 10-16 | |||||||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||||||

| Dia. 10 | Dia. 12 | Dia. 14 | Dia. 16 | ||||||||

| min. | max. | min. | max. | min. | max. | min. | max. | ||||

| Steels | |||||||||||

| High-speed steels | < 1,300 N/mm² | E | 112 | 0,044 | 0,066 | 0,056 | 0,084 | 0,058 | 0,088 | 0,074 | 0,112 |

| Tool steels | < 1,300 N/mm² | E | 180 | 0,044 | 0,066 | 0,056 | 0,084 | 0,058 | 0,088 | 0,074 | 0,112 |

| Stainless steels | |||||||||||

| Hardened steels | 40-48 HRC | L | 60 | 0,038 | 0,058 | 0,050 | 0,074 | 0,056 | 0,084 | 0,062 | 0,094 |

| Hardened steels | 45-55 HRC | L | 48 | 0,034 | 0,050 | 0,044 | 0,068 | 0,050 | 0,074 | 0,056 | 0,084 |

| Hardened steels | 55-60 HRC | L | 48 | 0,034 | 0,050 | 0,044 | 0,068 | 0,050 | 0,074 | 0,056 | 0,084 |

| Hardened steels | 60-65 HRC | L | 32 | 0,024 | 0,036 | 0,028 | 0,044 | 0,038 | 0,058 | 0,044 | 0,064 |

| Cast metals | |||||||||||

| Cast iron, lamellar graphite | < 180 HB | L + E | 180 | 0,062 | 0,094 | 0,076 | 0,114 | 0,091 | 0,137 | 0,110 | 0,166 |

| Cast iron, lamellar graphite | > 260 HB | L + E | 144 | 0,052 | 0,078 | 0,058 | 0,086 | 0,066 | 0,100 | 0,078 | 0,116 |

| Nodular graphite, malleable iron | > 260 HB | L + E | 140 | 0,052 | 0,078 | 0,058 | 0,086 | 0,066 | 0,100 | 0,078 | 0,116 |