Drilling screw, round head with AW drive and sealing washer piasta®

piasta stainless steel A2 zinc-flake w. washer AW

SCR-DBIT-PANHD-WSH12/2-AW20-(RUS)-4,8X25

ZEBRA PIASTA

price per selected packing unit | Individual prices for customers after login

Register now and access more than 125,000 products

The sealing washer consists of a stainless steel A2 metal backing with vulcanized Seal made of high-quality EPDM

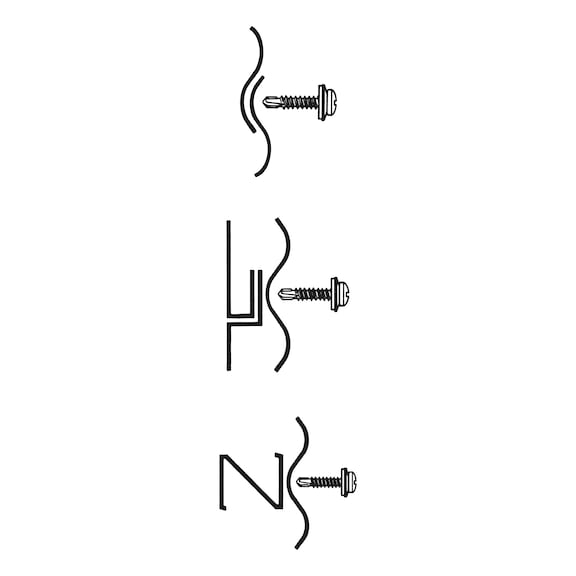

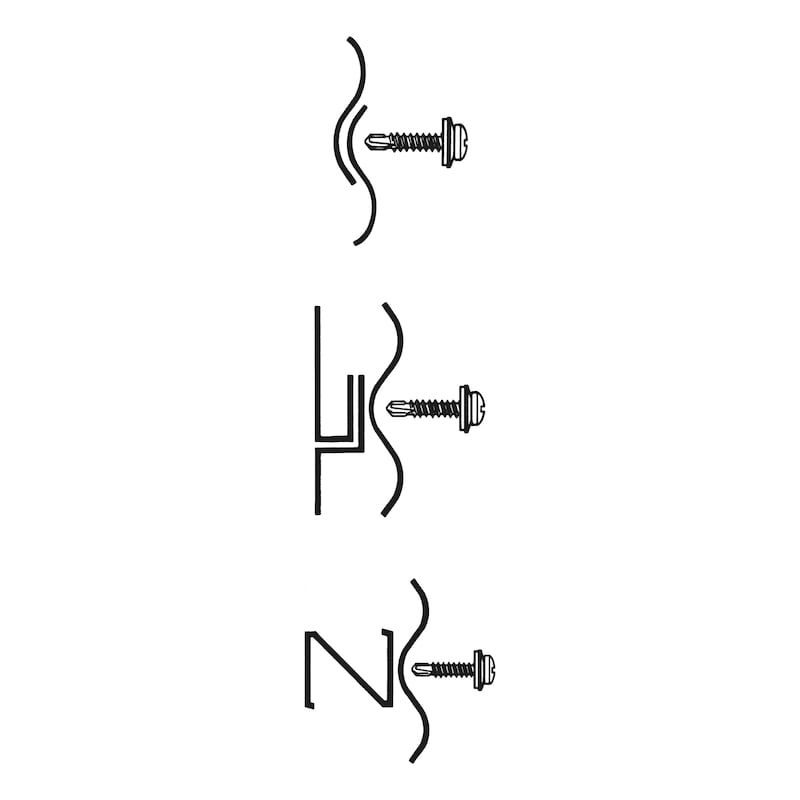

The screw with the sealing washer ∅ 14 mm, 3 mm EPDM is particularly suitable for fastening shaft profiles (e.g. 18/76)

Additional optimum torque transmission by the AW drive

Suitable for component combinations tI / tII according to approval ETA-10/0184

- Steel / steel

- Alu/steel.

- ALU/ALU

Datasheets(X)

| |

Material | Bimetal |

Surface | Flake zinc |

Material of sealing washer | Stainless steel A2 |

Surface of the sealing washer | Plain |

Material of gasket | Ethylene propylene diene terpolymer rubber |

RoHS-compliant | Yes |

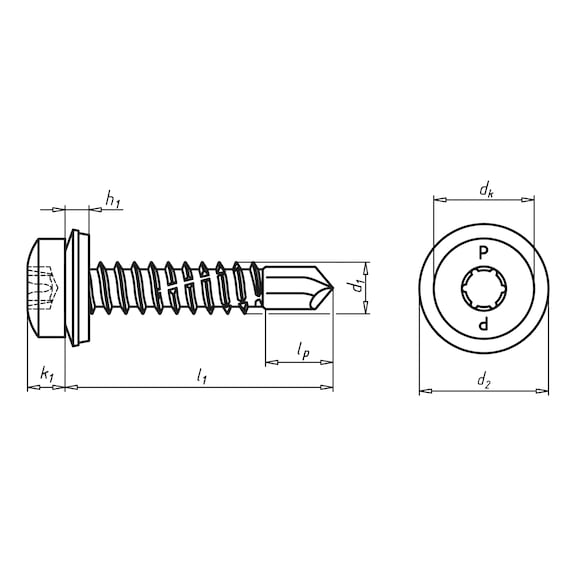

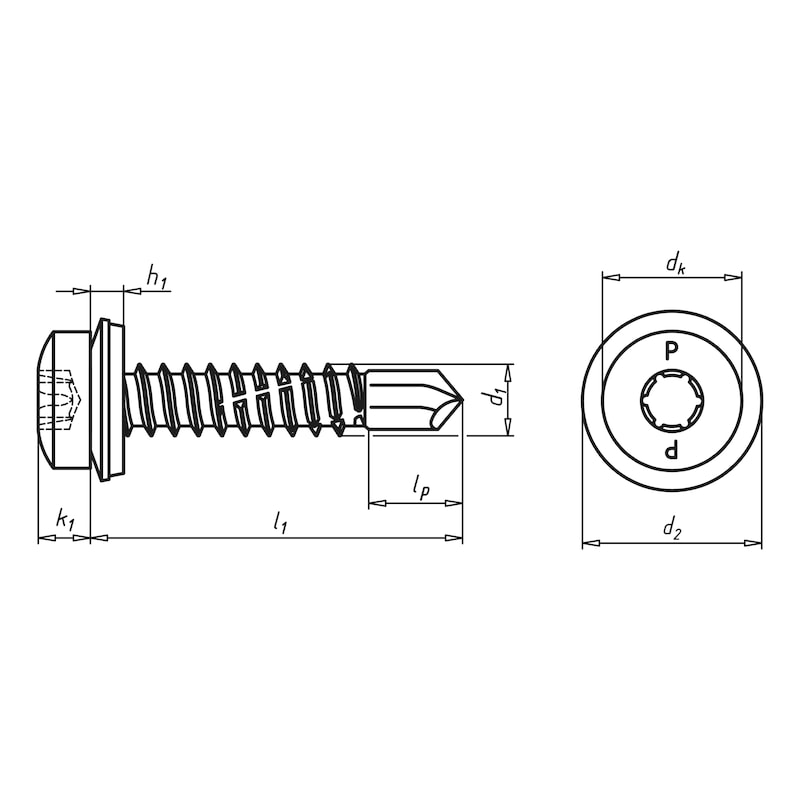

Head type | Pan head |

Drive type | AW |

Thread type | Self-tapping screw thread |

Shape of tip | Drilling tip |

Underground | Steel |

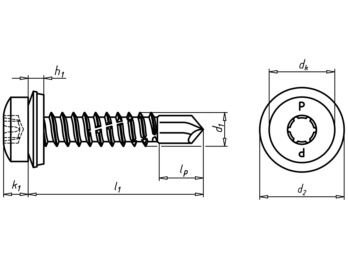

Nominal diameter (d1) | 4.8 mm |

Length (l1) | 25 mm |

Head diameter (dk) | 9.5 mm |

Outside diameter of the sealing washer (d2) | 12 mm |

Washer thickness (h1) | 2 mm |

Head height (k1) | 3.5 mm |

Drill tip length (lp) | 4.5 mm |

Screw-thread length with drill tip | 22.5 mm |

Internal drive | AW20 |

Min. recommended substructure thickness | 1.5 mm |

Max. material thickness to be drilled through (metal) | 4.4 mm |

For max. substructure thickness | 3 mm |

Min./max. attachment thickness | 0-9 mm |

Approval | ETA-10/0184 |

Min./max. recommended installation speed (idling) | 1700-2500 rpm |