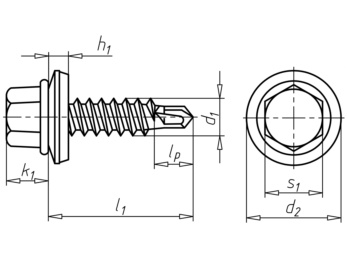

Drilling screw, hexagon head with reduced drill tip and sealing washer piasta®

piasta sst zinc-flake reduced drill tip w. washer

SCR-DBITR-WSH16-WS3/8-(RUS)-6,3X25

Art.-no. 0214886325

EAN 4011231276368

price per selected packing unit | Individual prices for customers after login

Register now and access more than 125,000 products

The sealing washer consists of an A2 stainless steel metal back with vulcanised seal made of high-quality EPDM

Reduction of the assembly time using the drill bit tip by min. 50%:

- Drilling without centrepunching

- Thread moulding

- Securing

All in one operation

Suitable for component combinations tI / tII according to approval ETA-10/0184

- Steel/steel - for ∅ 4.8 mm and 6.3 mm

- Aluminium/steel - for ∅ 6.3 mm

- Aluminium/aluminium - for ∅ 6.3 mm

Datasheets(X)

| |

Material | Bimetal |

Surface | Flake zinc |

Material of sealing washer | Stainless steel A2 |

Surface of the sealing washer | Plain |

Material of gasket | Ethylene propylene diene terpolymer rubber |

RoHS-compliant | Yes |

Head type | Hexagon head with collar |

Drive type | Hexagon |

Thread type | Self-tapping screw thread |

Shape of tip | Drilling tip |

Underground | Steel, Aluminum |

Nominal diameter (d1) | 6.3 mm |

Length (l1) | 25 mm |

Head diameter (dk) | 13.2 mm |

Outside diameter of the sealing washer (d2) | 16 mm |

Washer thickness (h1) | 3 mm |

Head height (k1) | 6.8 mm |

Drill tip length (lp) | 4.5 mm |

Screw-thread length with drill tip | 24 mm |

External drive (s1) | WS3/8 |

Max. material thickness to be drilled through (metal) | 2.5 mm |

For max. substructure thickness | 1.5 mm |

Min./max. attachment thickness | 0-7 mm |

Approval | ETA-10/0184 |

Min./max. recommended installation speed (idling) | 1200-1800 rpm |