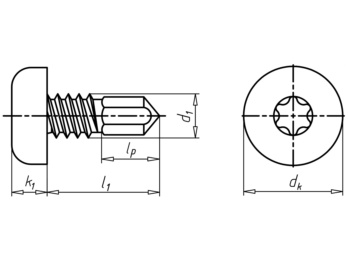

Drilling screw, flat head with AW drive and minipoint pias®

pias Minipoint steel zinc-plated AW

SCR-DBIT-PANHD-SHT-AW20-(A3K)-M4X10

Art.-no. 0206000410

EAN 4045727654675

price per selected packing unit | Individual prices for customers after login

Register now and access more than 125,000 products

Especially suitable for thin sheet metal

Zinc-plated steel, blue passivated (A3K)

With metric thread

Drilling, thread forming, screwing in: all in one step

Therefore considerably reduced time and effort

Exact drilling diameter for any screw connection

- Minimisation of thread tolerance

- Always an optimum connection

Prevents mistakes in the installation

AW drive system:

- Enhanced torque transmission

- Longer service life

- Optimum centring

- Improved performance thanks to fatigue-free screwing in; the required contact pressure for transmission of the torques is considerably lower

- Largest possible contact surface of bit in screw drive

- Even force distribution prevents damage to the surface-protection coating and therefore ensures better resistance to corrosion

- Drilling screws must be processed with a suitable drill driver (e.g. cordless drill driver with depth stop)

- The use of impact screwdrivers is not permitted

- Drilling screws must be attached perpendicular to the surface of the component

Galvanized drilling screws may only be used where dampness is not to be expected. For fasteners with a construction permit, the permit, and in particular Part 2 "Special regulations", must always be observed.

Datasheets(X)

| |

Material | Steel |

Surface | Zinc plated |

RoHS-compliant | Yes |

Head type | Flat head |

Drive type | AW |

Thread type | Metric thread |

Shape of tip | Drilling tip |

Nominal diameter (d1) | 4 mm |

Length (l1) | 10 mm |

Head diameter (dk) | 8.2 mm |

Head height (k1) | 3.1 mm |

Drill tip length (lp) | 6 mm |

Internal drive | AW20 |

Min. recommended substructure thickness | 0.3 mm |

Max. material thickness to be drilled through (metal) | 2 mm |

Min./max. recommended installation speed (idling) | 1700-2500 rpm |