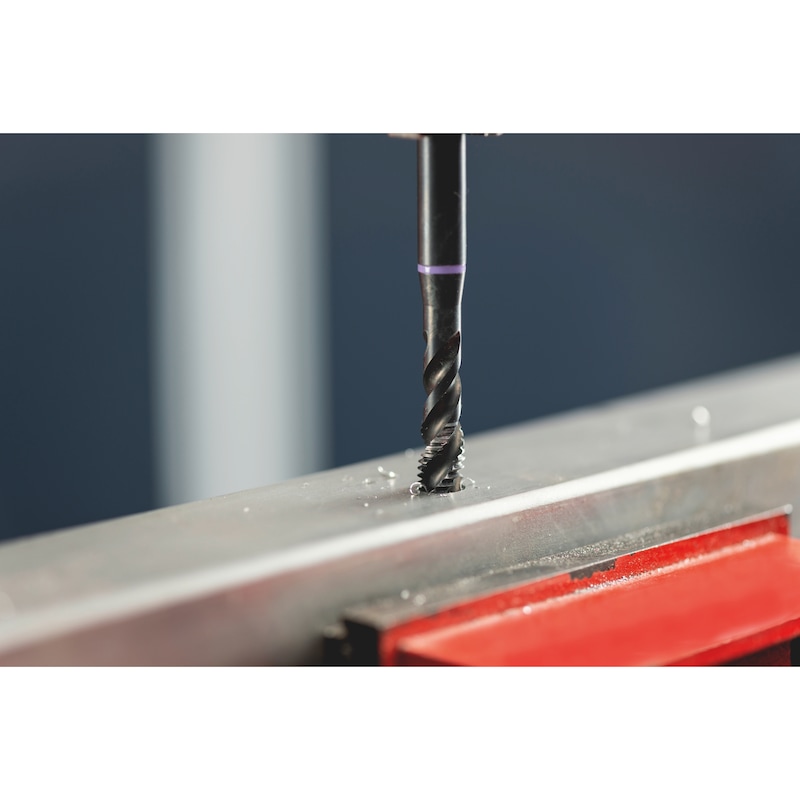

HSCo Multi Performance machine tap for blind holes DIN 371/376

Machine screw tap HSCo multi Performance form C

MATAP-BLIHO-HSCO-DIN376-MULTI-PERFM-M14

ZEBRA

price per selected packing unit | Individual prices for customers after login

Register now and access more than 125,000 products

Flexible use in cordless drills and hand-held, free-standing and pillar drills

The polygon shaft prevents spinning in the drill chuck, ensures optimal power transmission and protects the drill chuck from damage.

Suitable for conventional applications, such as in CNC machining centres with collets or compensation chucks

Straight shaft held in place by the square mount

For process reliability in almost all materials

Newly developed tool geometry with reduced rake angle as well as optimised clearance angle and microgeometry

Outstanding performance

Excellent chip removal, prevents chip accumulation

Available exclusively from Würth

- Sufficient coolant and lubricant must be added when cutting threads.

- For the machine tap/material assignments, see the overview tables

Datasheets(X)

Thread type | Metric thread |

Material to be processed | Steel |

Hole type | Blind hole ≤ 2.5xD |

Suitable for machine type | Drill |

Quality | ZEBRA-Premium |

Thread type x nominal diameter | M14 |

Pitch | 2 mm |

Length | 110 mm |

Shank diameter | 11 mm |

Size of square | 9 mm |

DIN | 376 |

Cutting material | HSCo |

Surface | Vaporised |

Form | C |

Core hole diameter | 12 mm |

Twist angle | 45° (right) |

Shank style | Cylindrical with square drive |

Tolerance of screw taps | ISO 2X (6HX) |

Suitable for tensile strength up to | 1200 N/mm² |

Service life (points system) | 3 of 4 points |

Trueness to gauge (points system) | 4 of 4 points |

Versatility (points system) | 4 of 4 points |

Cutting behaviour (points system) | 4 of 4 points |

Chip formation (points system) | 3 of 4 points |

Material of sub-group | General structural steels |

| Cutting values | ||||||||||||

| For M2-M3 | ||||||||||||

| Material designation | Tensile strength | M2 | M2.5 | M3 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| General structural steels | < 850 N/mm² | 15 | 20 | 2387 | 3183 | 0,40 | 1910 | 2547 | 0,45 | 1592 | 2122 | 0,50 |

| Unalloyed quenched and tempered steels | < 850 N/mm² | 15 | 20 | 2387 | 3183 | 0,40 | 1910 | 2547 | 0,45 | 1592 | 2122 | 0,50 |

| Low-alloy quenched and tempered steels | < 850 N/mm² | 15 | 20 | 2387 | 3183 | 0,40 | 1910 | 2547 | 0,45 | 1592 | 2122 | 0,50 |

| Unalloyed quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 1592 | 2387 | 0,40 | 1273 | 1910 | 0,45 | 1061 | 1592 | 0,50 |

| Low-alloy quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 1592 | 2387 | 0,40 | 1273 | 1910 | 0,45 | 1061 | 1592 | 0,50 |

| Alloyed quenched and tempered steels | < 1,200 N/mm² | 6 | 8 | 955 | 1273 | 0,40 | 764 | 1019 | 0,45 | 637 | 849 | 0,50 |

| Nitriding steels | < 1,200 N/mm² | 6 | 8 | 955 | 1273 | 0,40 | 764 | 1019 | 0,45 | 637 | 849 | 0,50 |

| Tool steels | < 1,200 N/mm² | 6 | 8 | 955 | 1273 | 0,40 | 764 | 1019 | 0,45 | 637 | 849 | 0,50 |

| High-speed steels | < 1,200 N/mm² | 6 | 8 | 955 | 1273 | 0,40 | 764 | 1019 | 0,45 | 637 | 849 | 0,50 |

| High-grade steels | ||||||||||||

| Stainless steels | < 1,200 N/mm² | 5 | 8 | 796 | 1273 | 0,40 | 637 | 1019 | 0,45 | 531 | 849 | 0,50 |

| Titanium | < 850 N/mm² | 2 | 3 | 318 | 477 | 0,40 | 255 | 382 | 0,45 | 212 | 318 | 0,50 |

| Special alloys | < 1,200 N/mm² | 2 | 3 | 318 | 477 | 0,40 | 255 | 382 | 0,45 | 212 | 318 | 0,50 |

| Cast metals | ||||||||||||

| Cast iron | < 300 HB | 10 | 15 | 1592 | 2387 | 0,40 | 1273 | 1910 | 0,45 | 1061 | 1592 | 0,50 |

| Spheroidal graphite and malleable iron | < 350 HB | 8 | 12 | 1273 | 1910 | 0,40 | 1019 | 1582 | 0,45 | 849 | 1273 | 0,50 |

| Hard materials | ||||||||||||

| Hardox | < 1,400 N/mm² | 2 | 3 | 318 | 477 | 0,40 | 255 | 382 | 0,45 | 212 | 318 | 0,50 |

| Spring steels | < 1,100 N/mm² | 2 | 3 | 318 | 477 | 0,40 | 255 | 382 | 0,45 | 212 | 318 | 0,50 |

| Non-ferrous metals | ||||||||||||

| Aluminium | < 450 N/mm² | 15 | 20 | 2387 | 3183 | 0,40 | 1910 | 2547 | 0,45 | 1592 | 2122 | 0,50 |

| Aluminium alloys | < 450 N/mm² | 15 | 20 | 2387 | 3183 | 0,40 | 1910 | 2547 | 0,45 | 1592 | 2122 | 0,50 |

| Aluminium wrought alloys | < 400 N/mm² | 15 | 20 | 2387 | 3183 | 0,40 | 1910 | 2547 | 0,45 | 1592 | 2122 | 0,50 |

| Aluminium cast alloys <= 10 % Si | < 600 N/mm² | 15 | 20 | 1592 | 2387 | 0,40 | 1273 | 1910 | 0,45 | 1061 | 1592 | 0,50 |

| Low-alloy copper | < 400 N/mm² | 15 | 20 | 2387 | 3183 | 0,40 | 1910 | 2547 | 0,45 | 1592 | 2122 | 0,50 |

| Long-chipping brass | < 600 N/mm² | 15 | 20 | 2387 | 3183 | 0,40 | 1910 | 2547 | 0,45 | 1592 | 2122 | 0,50 |

| Long-chipping bronze | < 1,000 N/mm² | 15 | 20 | 2387 | 3183 | 0,40 | 1910 | 2547 | 0,45 | 1592 | 2122 | 0,50 |

| Thermosetting plastics | 4 | 6 | 637 | 955 | 0,40 | 509 | 764 | 0,45 | 424 | 637 | 0,50 | |

| Thermoplastic plastics | 4 | 6 | 637 | 955 | 0,40 | 509 | 764 | 0,45 | 424 | 637 | 0,50 | |

| For M4-M6 | ||||||||||||

| Material designation | Tensile strength | M4 | M5 | M6 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| General structural steels | < 850 N/mm² | 15 | 20 | 1194 | 1592 | 0,70 | 955 | 1273 | 0,80 | 796 | 1061 | 1,00 |

| Unalloyed quenched and tempered steels | < 850 N/mm² | 15 | 20 | 1194 | 1592 | 0,70 | 955 | 1273 | 0,80 | 796 | 1061 | 1,00 |

| Low-alloy quenched and tempered steels | < 850 N/mm² | 15 | 20 | 1194 | 1592 | 0,70 | 955 | 1273 | 0,80 | 796 | 1061 | 1,00 |

| Unalloyed quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 796 | 1194 | 0,70 | 637 | 955 | 0,80 | 531 | 796 | 1,00 |

| Low-alloy quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 796 | 1194 | 0,70 | 637 | 955 | 0,80 | 531 | 796 | 1,00 |

| Alloyed quenched and tempered steels | < 1,200 N/mm² | 6 | 8 | 477 | 637 | 0,70 | 382 | 509 | 0,80 | 318 | 424 | 1,00 |

| Nitriding steels | < 1,200 N/mm² | 6 | 8 | 477 | 637 | 0,70 | 382 | 509 | 0,80 | 318 | 424 | 1,00 |

| Tool steels | < 1,200 N/mm² | 6 | 8 | 477 | 637 | 0,70 | 382 | 509 | 0,80 | 318 | 424 | 1,00 |

| High-speed steels | < 1,200 N/mm² | 6 | 8 | 477 | 637 | 0,70 | 382 | 509 | 0,80 | 318 | 424 | 1,00 |

| High-grade steels | ||||||||||||

| Stainless steels | < 1,200 N/mm² | 5 | 8 | 398 | 637 | 0,70 | 318 | 509 | 0,80 | 265 | 424 | 1,00 |

| Titanium | < 850 N/mm² | 2 | 3 | 159 | 239 | 0,70 | 127 | 191 | 0,80 | 106 | 159 | 1,00 |

| Special alloys | < 1,200 N/mm² | 2 | 3 | 159 | 239 | 0,70 | 127 | 191 | 0,80 | 106 | 159 | 1,00 |

| Cast metals | ||||||||||||

| Cast iron | < 300 HB | 10 | 15 | 796 | 1194 | 0,70 | 637 | 955 | 0,80 | 531 | 796 | 1,00 |

| Spheroidal graphite and malleable iron | < 350 HB | 8 | 12 | 637 | 955 | 0,70 | 509 | 764 | 0,80 | 424 | 637 | 1,00 |

| Hard materials | ||||||||||||

| Hardox | < 1,400 N/mm² | 2 | 3 | 159 | 239 | 0,70 | 127 | 191 | 0,80 | 106 | 159 | 1,00 |

| Spring steels | < 1,100 N/mm² | 2 | 3 | 159 | 239 | 0,70 | 127 | 191 | 0,80 | 106 | 159 | 1,00 |

| Non-ferrous metals | ||||||||||||

| Aluminium | < 450 N/mm² | 15 | 20 | 1194 | 1592 | 0,70 | 955 | 1273 | 0,80 | 796 | 1061 | 1,00 |

| Aluminium alloys | < 450 N/mm² | 15 | 20 | 1194 | 1592 | 0,70 | 955 | 1273 | 0,80 | 796 | 1061 | 1,00 |

| Aluminium wrought alloys | < 400 N/mm² | 15 | 20 | 1194 | 1592 | 0,70 | 955 | 1273 | 0,80 | 796 | 1061 | 1,00 |

| Aluminium cast alloys <= 10 % Si | < 600 N/mm² | 15 | 20 | 796 | 1194 | 0,70 | 637 | 955 | 0,80 | 531 | 796 | 1,00 |

| Low-alloy copper | < 400 N/mm² | 15 | 20 | 1194 | 1592 | 0,70 | 955 | 1273 | 0,80 | 796 | 1061 | 1,00 |

| Long-chipping brass | < 600 N/mm² | 15 | 20 | 1194 | 1592 | 0,70 | 955 | 1273 | 0,80 | 796 | 1061 | 1,00 |

| Long-chipping bronze | < 1,000 N/mm² | 15 | 20 | 1194 | 1592 | 0,70 | 955 | 1273 | 0,80 | 796 | 1061 | 1,00 |

| Thermosetting plastics | 4 | 6 | 318 | 477 | 0,70 | 255 | 382 | 0,80 | 212 | 318 | 1,00 | |

| Thermoplastic plastics | 4 | 6 | 318 | 477 | 0,70 | 255 | 382 | 0,80 | 212 | 318 | 1,00 | |

| For M8-M12 | ||||||||||||

| Material designation | Tensile strength | M8 | M10 | M12 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| General structural steels | < 850 N/mm² | 15 | 20 | 597 | 796 | 1,25 | 477 | 637 | 1,50 | 398 | 531 | 1,75 |

| Unalloyed quenched and tempered steels | < 850 N/mm² | 15 | 20 | 597 | 796 | 1,25 | 477 | 637 | 1,50 | 398 | 531 | 1,75 |

| Low-alloy quenched and tempered steels | < 850 N/mm² | 15 | 20 | 597 | 796 | 1,25 | 477 | 637 | 1,50 | 398 | 531 | 1,75 |

| Unalloyed quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 398 | 597 | 1,25 | 318 | 477 | 1,50 | 265 | 398 | 1,75 |

| Low-alloy quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 398 | 597 | 1,25 | 318 | 477 | 1,50 | 265 | 398 | 1,75 |

| Alloyed quenched and tempered steels | < 1,200 N/mm² | 6 | 8 | 239 | 318 | 1,25 | 191 | 255 | 1,50 | 159 | 212 | 1,75 |

| Nitriding steels | < 1,200 N/mm² | 6 | 8 | 239 | 318 | 1,25 | 191 | 255 | 1,50 | 159 | 212 | 1,75 |

| Tool steels | < 1,200 N/mm² | 6 | 8 | 239 | 318 | 1,25 | 191 | 255 | 1,50 | 159 | 212 | 1,75 |

| High-speed steels | < 1,200 N/mm² | 6 | 8 | 239 | 318 | 1,25 | 191 | 255 | 1,50 | 159 | 212 | 1,75 |

| High-grade steels | ||||||||||||

| Stainless steels | < 1,200 N/mm² | 5 | 8 | 199 | 318 | 1,25 | 159 | 255 | 1,50 | 133 | 212 | 1,75 |

| Titanium | < 850 N/mm² | 2 | 3 | 80 | 119 | 1,25 | 64 | 95 | 1,50 | 53 | 80 | 1,75 |

| Special alloys | < 1,200 N/mm² | 2 | 3 | 80 | 119 | 1,25 | 64 | 95 | 1,50 | 53 | 80 | 1,75 |

| Cast metals | ||||||||||||

| Cast iron | < 300 HB | 10 | 15 | 398 | 597 | 1,25 | 318 | 477 | 1,50 | 265 | 398 | 1,75 |

| Spheroidal graphite and malleable iron | < 350 HB | 8 | 12 | 318 | 477 | 1,25 | 255 | 382 | 1,50 | 212 | 318 | 1,75 |

| Hard materials | ||||||||||||

| Hardox | < 1,400 N/mm² | 2 | 3 | 80 | 119 | 1,25 | 64 | 95 | 1,50 | 53 | 80 | 1,75 |

| Spring steels | < 1,100 N/mm² | 2 | 3 | 80 | 119 | 1,25 | 64 | 95 | 1,50 | 53 | 80 | 1,75 |

| Non-ferrous metals | ||||||||||||

| Aluminium | < 450 N/mm² | 15 | 20 | 597 | 796 | 1,25 | 477 | 637 | 1,50 | 398 | 531 | 1,75 |

| Aluminium alloys | < 450 N/mm² | 15 | 20 | 597 | 796 | 1,25 | 477 | 637 | 1,50 | 398 | 531 | 1,75 |

| Aluminium wrought alloys | < 400 N/mm² | 15 | 20 | 597 | 796 | 1,25 | 477 | 637 | 1,50 | 398 | 531 | 1,75 |

| Aluminium cast alloys <= 10 % Si | < 600 N/mm² | 15 | 20 | 398 | 597 | 1,25 | 318 | 477 | 1,50 | 265 | 398 | 1,75 |

| Low-alloy copper | < 400 N/mm² | 15 | 20 | 597 | 796 | 1,25 | 477 | 637 | 1,50 | 398 | 531 | 1,75 |

| Long-chipping brass | < 600 N/mm² | 15 | 20 | 597 | 796 | 1,25 | 477 | 637 | 1,50 | 398 | 531 | 1,75 |

| Long-chipping bronze | < 1,000 N/mm² | 15 | 20 | 597 | 796 | 1,25 | 477 | 637 | 1,50 | 398 | 531 | 1,75 |

| Thermosetting plastics | 4 | 6 | 159 | 239 | 1,25 | 127 | 191 | 1,50 | 106 | 159 | 1,75 | |

| Thermoplastic plastics | 4 | 6 | 159 | 239 | 1,25 | 127 | 191 | 1,50 | 106 | 159 | 1,75 | |

| For M14-M20 | ||||||||||||

| Material designation | Tensile strength | M14 | M16 | M20 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| General structural steels | < 850 N/mm² | 15 | 20 | 341 | 455 | 2,00 | 298 | 398 | 2,00 | 239 | 318 | 2,50 |

| Unalloyed quenched and tempered steels | < 850 N/mm² | 15 | 20 | 341 | 455 | 2,00 | 298 | 398 | 2,00 | 239 | 318 | 2,50 |

| Low-alloy quenched and tempered steels | < 850 N/mm² | 15 | 20 | 341 | 455 | 2,00 | 298 | 398 | 2,00 | 239 | 318 | 2,50 |

| Unalloyed quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 227 | 341 | 2,00 | 199 | 298 | 2,00 | 159 | 239 | 2,50 |

| Low-alloy quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 227 | 341 | 2,00 | 199 | 298 | 2,00 | 159 | 239 | 2,50 |

| Alloyed quenched and tempered steels | < 1,200 N/mm² | 6 | 8 | 136 | 182 | 2,00 | 119 | 159 | 2,00 | 95 | 127 | 2,50 |

| Nitriding steels | < 1,200 N/mm² | 6 | 8 | 136 | 182 | 2,00 | 119 | 159 | 2,00 | 95 | 127 | 2,50 |

| Tool steels | < 1,200 N/mm² | 6 | 8 | 136 | 182 | 2,00 | 119 | 159 | 2,00 | 95 | 127 | 2,50 |

| High-speed steels | < 1,200 N/mm² | 6 | 8 | 136 | 182 | 2,00 | 119 | 159 | 2,00 | 95 | 127 | 2,50 |

| High-grade steels | ||||||||||||

| Stainless steels | < 1,200 N/mm² | 5 | 8 | 114 | 182 | 2,00 | 99 | 159 | 2,00 | 80 | 127 | 2,50 |

| Titanium | < 850 N/mm² | 2 | 3 | 45 | 68 | 2,00 | 40 | 60 | 2,00 | 32 | 48 | 2,50 |

| Special alloys | < 1,200 N/mm² | 2 | 3 | 45 | 68 | 2,00 | 40 | 60 | 2,00 | 32 | 48 | 2,50 |

| Cast metals | ||||||||||||

| Cast iron | < 300 HB | 10 | 15 | 227 | 341 | 2,00 | 199 | 298 | 2,00 | 159 | 239 | 2,50 |

| Spheroidal graphite and malleable iron | < 350 HB | 8 | 12 | 182 | 273 | 2,00 | 159 | 239 | 2,00 | 127 | 191 | 2,50 |

| Hard materials | ||||||||||||

| Hardox | < 1,400 N/mm² | 2 | 3 | 45 | 68 | 2,00 | 40 | 60 | 2,00 | 32 | 48 | 2,50 |

| Spring steels | < 1,100 N/mm² | 2 | 3 | 45 | 68 | 2,00 | 40 | 60 | 2,00 | 32 | 48 | 2,50 |

| Non-ferrous metals | ||||||||||||

| Aluminium | < 450 N/mm² | 15 | 20 | 341 | 455 | 2,00 | 298 | 398 | 2,00 | 239 | 318 | 2,50 |

| Aluminium alloys | < 450 N/mm² | 15 | 20 | 341 | 455 | 2,00 | 298 | 398 | 2,00 | 239 | 318 | 2,50 |

| Aluminium wrought alloys | < 400 N/mm² | 15 | 20 | 341 | 455 | 2,00 | 298 | 398 | 2,00 | 239 | 318 | 2,50 |

| Aluminium cast alloys <= 10 % Si | < 600 N/mm² | 15 | 20 | 227 | 341 | 2,00 | 199 | 298 | 2,00 | 159 | 239 | 2,50 |

| Low-alloy copper | < 400 N/mm² | 15 | 20 | 341 | 455 | 2,00 | 298 | 398 | 2,00 | 239 | 318 | 2,50 |

| Long-chipping brass | < 600 N/mm² | 15 | 20 | 341 | 455 | 2,00 | 298 | 398 | 2,00 | 239 | 318 | 2,50 |

| Long-chipping bronze | < 1,000 N/mm² | 15 | 20 | 341 | 455 | 2,00 | 298 | 398 | 2,00 | 239 | 318 | 2,50 |

| Thermosetting plastics | 4 | 6 | 91 | 136 | 2,00 | 80 | 119 | 2,00 | 64 | 95 | 2,50 | |

| Thermoplastic plastics | 4 | 6 | 91 | 136 | 2,00 | 80 | 119 | 2,00 | 64 | 95 | 2,50 | |

| For M24-M30 | |||||||||

| Material designation | Tensile strength | M24 | M30 | ||||||

| vc | n | f | n | f | |||||

| from | to | from | to | from | to | ||||

| Steels | |||||||||

| General structural steels | < 850 N/mm² | 15 | 20 | 199 | 265 | 3,00 | 159 | 212 | 3,50 |

| Unalloyed quenched and tempered steels | < 850 N/mm² | 15 | 20 | 199 | 265 | 3,00 | 159 | 212 | 3,50 |

| Low-alloy quenched and tempered steels | < 850 N/mm² | 15 | 20 | 199 | 265 | 3,00 | 159 | 212 | 3,50 |

| Unalloyed quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 133 | 199 | 3,00 | 106 | 159 | 3,50 |

| Low-alloy quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 133 | 199 | 3,00 | 106 | 159 | 3,50 |

| Alloyed quenched and tempered steels | < 1,200 N/mm² | 6 | 8 | 80 | 106 | 3,00 | 64 | 85 | 3,50 |

| Nitriding steels | < 1,200 N/mm² | 6 | 8 | 80 | 106 | 3,00 | 64 | 85 | 3,50 |

| Tool steels | < 1,200 N/mm² | 6 | 8 | 80 | 106 | 3,00 | 64 | 85 | 3,50 |

| High-speed steels | < 1,200 N/mm² | 6 | 8 | 80 | 106 | 3,00 | 64 | 85 | 3,50 |

| High-grade steels | |||||||||

| Stainless steels | < 1,200 N/mm² | 5 | 8 | 66 | 106 | 3,00 | 53 | 85 | 3,50 |

| Titanium | < 850 N/mm² | 2 | 3 | 27 | 40 | 3,00 | 21 | 32 | 3,50 |

| Special alloys | < 1,200 N/mm² | 2 | 3 | 27 | 40 | 3,00 | 21 | 32 | 3,50 |

| Cast metals | |||||||||

| Cast iron | < 300 HB | 10 | 15 | 133 | 199 | 3,00 | 106 | 159 | 3,50 |

| Spheroidal graphite and malleable iron | < 350 HB | 8 | 12 | 106 | 159 | 3,00 | 85 | 127 | 3,50 |

| Hard materials | |||||||||

| Hardox | < 1,400 N/mm² | 2 | 3 | 27 | 40 | 3,00 | 21 | 32 | 3,50 |

| Spring steels | < 1,100 N/mm² | 2 | 3 | 27 | 40 | 3,00 | 21 | 32 | 3,50 |

| Non-ferrous metals | |||||||||

| Aluminium | < 450 N/mm² | 15 | 20 | 199 | 265 | 3,00 | 159 | 212 | 3,50 |

| Aluminium alloys | < 450 N/mm² | 15 | 20 | 199 | 265 | 3,00 | 159 | 212 | 3,50 |

| Aluminium wrought alloys | < 400 N/mm² | 15 | 20 | 199 | 265 | 3,00 | 159 | 212 | 3,50 |

| Aluminium cast alloys <= 10 % Si | < 600 N/mm² | 15 | 20 | 133 | 199 | 3,00 | 106 | 159 | 3,50 |

| Low-alloy copper | < 400 N/mm² | 15 | 20 | 199 | 265 | 3,00 | 159 | 212 | 3,50 |

| Long-chipping brass | < 600 N/mm² | 15 | 20 | 199 | 265 | 3,00 | 159 | 212 | 3,50 |

| Long-chipping bronze | < 1,000 N/mm² | 15 | 20 | 199 | 265 | 3,00 | 159 | 212 | 3,50 |

| Thermosetting plastics | 4 | 6 | 53 | 80 | 3,00 | 42 | 64 | 3,50 | |

| Thermoplastic plastics | 4 | 6 | 53 | 80 | 3,00 | 42 | 64 | 3,50 | |

| Key |

| vc = cutting speed [m/min] |

| f = feed [mm/r] |

| n = rotation speed [rpm] |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |